Call: 708-425-9080

Vacuum Chamber Design: What is a Virtual Leak?

Confirming leak tightness with Helium Leak Detection requires designs that eliminate virtual leaks.

Confirming leak tightness with Helium Leak Detection requires designs that eliminate virtual leaks.

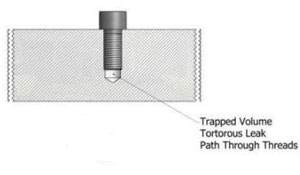

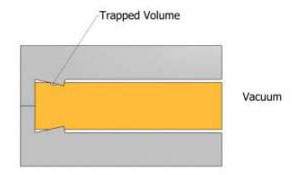

A virtual leak is a trapped volume of gas connected to the vacuum side of a chamber that can not be pumped out easily due to the restriction in the path connecting the trapped gas volume to the chamber volume. As the chamber pump down cycle crosses over from viscous to molecular flow, the gas molecules within the trapped volume can only be pumped out at a rate proportional to the conductance of the path between the trapped volume and the chamber volume. This rate is the “virtual leak”.

A virtual leak will not be detected in a normal helium leak testing cycle. The presence of a virtual leak will become apparent during the system pump down cycle if the vacuum pumps cannot keep up with the gas load from the virtual leak and ultimate pressures cannot be reached or take an excessive time to reach.

Poor design techniques or workmanship issues are the major cause of virtual leaks. They can also be caused by laminations in raw materials, but these are much rarer occurrences.

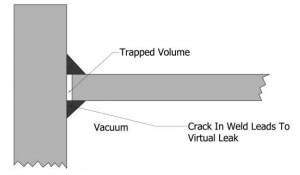

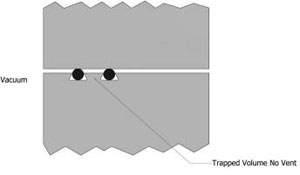

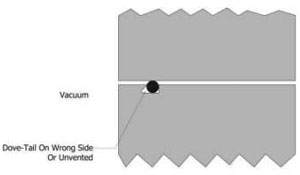

Common examples of virtual leaks caused by poor design are:

A virtual leak will not be detected in a normal helium leak testing cycle. The presence of a virtual leak will become apparent during the system pump down cycle if the vacuum pumps cannot keep up with the gas load from the virtual leak and ultimate pressures cannot be reached or take an excessive time to reach.

Poor design techniques or workmanship issues are the major cause of virtual leaks. They can also be caused by laminations in raw materials, but these are much rarer occurrences.

Common examples of virtual leaks caused by poor design are:

Common examples of virtual leaks caused by poor workmanship are:

Virtual leaks are easily avoided if good vacuum practice is followed in the design and fabrication of your chamber. Future articles will discuss these practices.

The engineering and manufacturing team at Meyer Tool has the experience to avoid the design and fabrication errors that can result in a virtual leak. Let us apply our Reduce Project Risk Process to your application so you too can experience receipt of ‘plug-and-play’ vacuum chambers or components. Established in 1969, Meyer Tool has over 50 years of experience manufacturing custom and OEM vacuum vessels and components. Our experience spans a wide range of materials, processes, and project sizes. Whether you’re building a single prototype or need production manufacturing support for your unique vacuum application, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs.

Working on a project that requires design and manufacturing expertise?

Give us a call at 708-425-9080 or fill out our RFQ form to get started!