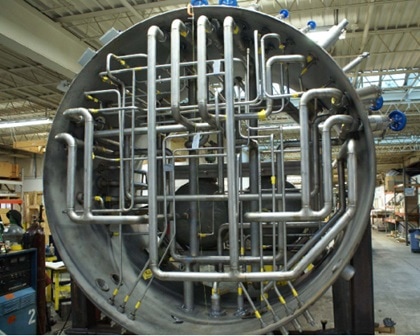

Pressure Vessel Products

ASME Code Vessels - Non ASME Code Vessels - ASME B31.3 Piping

We can design your pressure vessel project from scratch or we can build a vessel per your prints and specifications. We maintain an ASME "U" and National Board "R" stamp which certifies us to both fabricate and repair ASME code pressure vessels. We specialize in custom, prototype, or challenging pressure vessels designs in which we can showcase our differentiated fabrication skills. We are capable of streamlining a one of a kind prototype design, optimizing it for production, and producing mass quantity production runs at impeccable quality standards.