Call: 708-425-9080

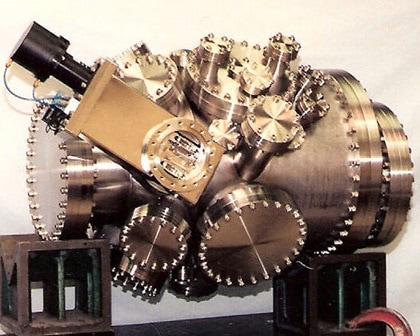

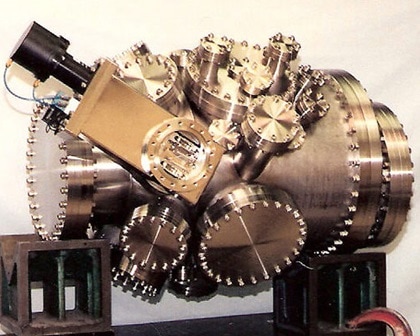

CUSTOM ULTRA HIGH VACUUM CHAMBERS (UHV)

Aluminum - Stainless Steel - Exotic Materials

Meyer Tool supplies custom chambers for ultra-high vacuum applications. We select the highest grades of materials consistent with UHV applications. In the manufacturing process only procedures and materials consistent with the UHV application are utilized, e.g. in the selection of machining coolant.

To minimize outgassing rates we adhere to stringent UHV cleaning procedures for all custom UHV chambers, which may include electropolishing or ultrasonic cleaning of vacuum surfaces. We maintain a cleanroom for final assembly of custom UHV vessels and equipment.

To minimize outgassing rates we adhere to stringent UHV cleaning procedures for all custom UHV chambers, which may include electropolishing or ultrasonic cleaning of vacuum surfaces. We maintain a cleanroom for final assembly of custom UHV vessels and equipment.