CRYOGENIC PRODUCTS

MLI - Dewars/Cryostats - Cold Boxes/Distribution Boxes

Heat Exchangers - Thermal Shrouds/Shields

"Cryogenic Products" can refer to a wide variety of different hardware components that are designed to operate at very low temperatures. Meyer Tool has been designing and fabricating cryogenic equipment for the particle accelerator industry and other advanced research applications since 1969. Our engineering and production staff is capable of designing and fabricating a wide array of custom cryogenic related products.

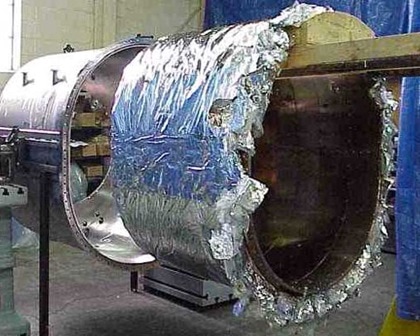

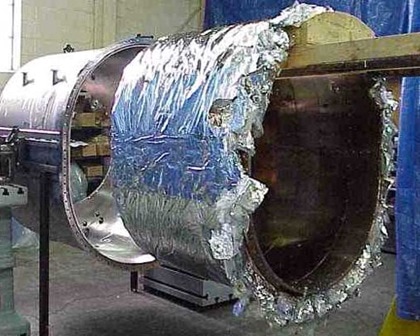

In most cases a cryogenic system will incorporate a mix of products that would include an outer vacuum shell, thermal shields, MLI insulation, internal pressure vessels, and internal piping spools.

The exact size, shape, and construction can vary depending on the application. We will work with you to design a custom solution to meet your performance requirements or optimize your existing design for fabrication and build it to your prints.

In most cases a cryogenic system will incorporate a mix of products that would include an outer vacuum shell, thermal shields, MLI insulation, internal pressure vessels, and internal piping spools.

The exact size, shape, and construction can vary depending on the application. We will work with you to design a custom solution to meet your performance requirements or optimize your existing design for fabrication and build it to your prints.