Call: 708-425-9080

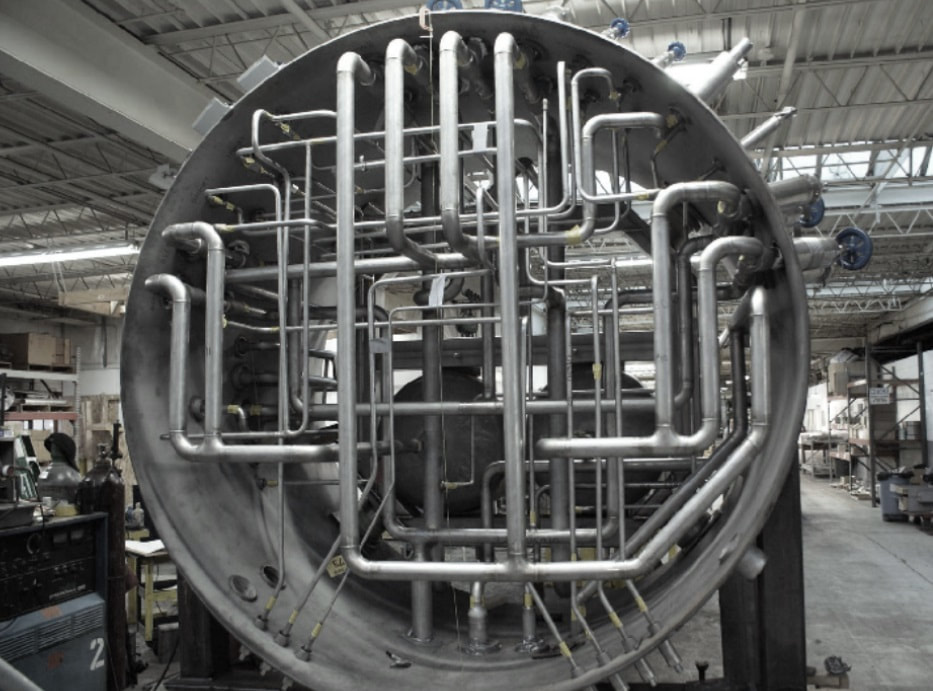

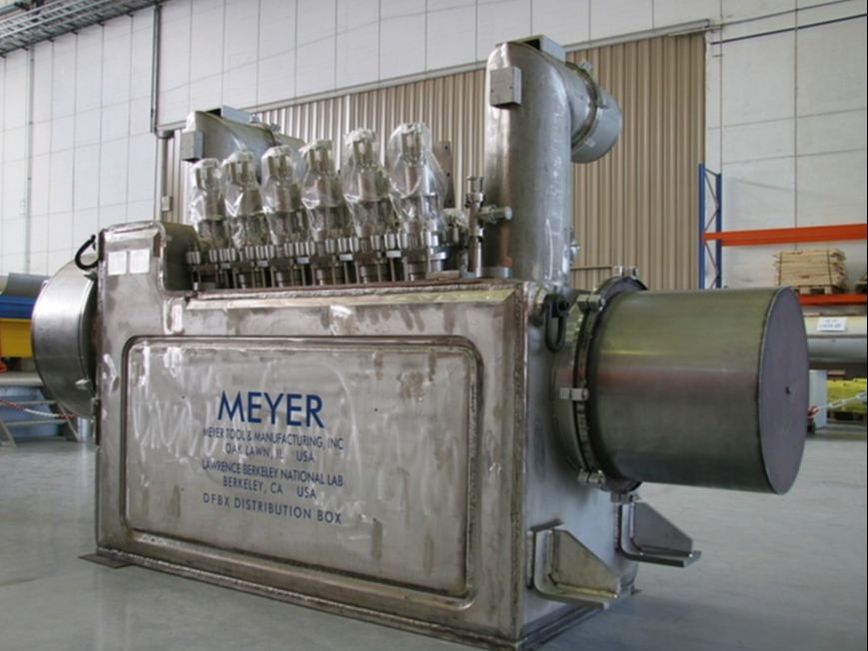

CUSTOM CRYOGENIC

DISTRIBUTION BOX / COLD BOX

Particle Accelerators - Industrial Process Systems

Meyer Tool has produced multiple variations of cryogenic distribution boxes over the years. Our highest profile distribution boxes are currently in use at the Large Hadron Collider, (LHC), installed at CERN in Switzerland. At Meyer Tool we take pride in knowing that our work producing cryogenic distribution boxes promotes the advancement of scientific research across a wide variety of disciplines.