Call: 708-425-9080

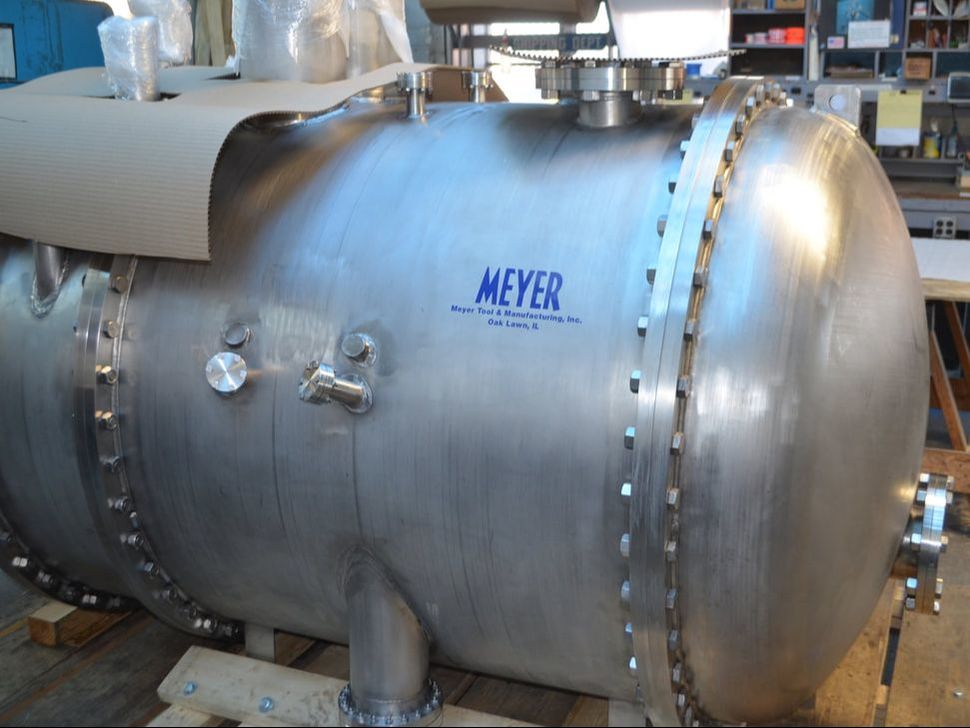

CUSTOM ASME CODE PRESSURE VESSELS

Design - Fabricate - Test - Prototype - Production

Meyer Tool & Mfg. has extensive experience in the design and manufacture of custom pressure vessels. Customers can choose an aluminum pressure vessel or a pressure vessel made up of alloy, stainless steel, carbon steel or copper. Our engineering team can provide advice on the choice of material used for custom pressure vessel depending on the application and the industry.

An aluminum custom pressure tank may be less expensive than the more traditional stainless steel, but stainless will have two to three times the strength of aluminum. Aluminum is easier to machine, but if you are looking at welded pressure vessels, the additional labor may negate steel’s advantage.

An aluminum custom pressure tank may be less expensive than the more traditional stainless steel, but stainless will have two to three times the strength of aluminum. Aluminum is easier to machine, but if you are looking at welded pressure vessels, the additional labor may negate steel’s advantage.

Create and Develop Custom Pressure Vessels to Your Needs

As experts in pressure vessel welding, we can provide advice on the right material choice for custom pressure tanks and pressure vessels. Depending on the size of the vessel and the pressure, there is a point where steel will become less expensive than an aluminum pressure vessel with the same strength and capacity. There are performance tradeoffs of shell ID versus thickness and shell ID versus weight.

Along with our design experience, our custom pressure vessel welding expertise and our experience in custom steel, copper or aluminum pressure vessel manufacturing, we also offer repair and refurbishment services to your pressure vessel made up of alloy, aluminum, steel or copper. Our repairs are fast and cost effective, and you can rely on the quality of your repaired pressure vessels. We understand that downtime is expensive, and we work with you to get you up and running quickly.

The company maintains an ASME Section VIII, Division 1, "U" stamp Certification for the design and manufacture of pressure vessels. Meyer Tool also maintains a Certificate of Authorization "R" stamp from the National Board of Boiler and Pressure Vessel Inspectors for repair of pressure vessels.

Our weld staff meets the requirements of ASME Section IX and the European Pressure Equipment Directive (PED) for a family of OEM pressure vessels.

Along with our design experience, our custom pressure vessel welding expertise and our experience in custom steel, copper or aluminum pressure vessel manufacturing, we also offer repair and refurbishment services to your pressure vessel made up of alloy, aluminum, steel or copper. Our repairs are fast and cost effective, and you can rely on the quality of your repaired pressure vessels. We understand that downtime is expensive, and we work with you to get you up and running quickly.

The company maintains an ASME Section VIII, Division 1, "U" stamp Certification for the design and manufacture of pressure vessels. Meyer Tool also maintains a Certificate of Authorization "R" stamp from the National Board of Boiler and Pressure Vessel Inspectors for repair of pressure vessels.

Our weld staff meets the requirements of ASME Section IX and the European Pressure Equipment Directive (PED) for a family of OEM pressure vessels.

Why Meyer Tool?

Meyer Tool is famous for providing a level of quality and support unmatched in the custom pressure vessel industry and in pressure vessel welding. We can build pressure vessel prototypes or in production quantities, and you can choose whether to have your pressure vessels ASME stamped or not.

High-quality ASME-stamped and certified custom pressure vessels from Meyer Tool provide peace of mind along with excellent performance while in operation. If expertise in pressure vessel welding and design are as important as productivity, efficiency and cost to your operation, you should be working with the best pressure vessel fabricator possible — Meyer Tool & Mfg. For more information or advice on the best way to meet your custom pressure vessel requirements, contact us today.

High-quality ASME-stamped and certified custom pressure vessels from Meyer Tool provide peace of mind along with excellent performance while in operation. If expertise in pressure vessel welding and design are as important as productivity, efficiency and cost to your operation, you should be working with the best pressure vessel fabricator possible — Meyer Tool & Mfg. For more information or advice on the best way to meet your custom pressure vessel requirements, contact us today.