Call: 708-425-9080

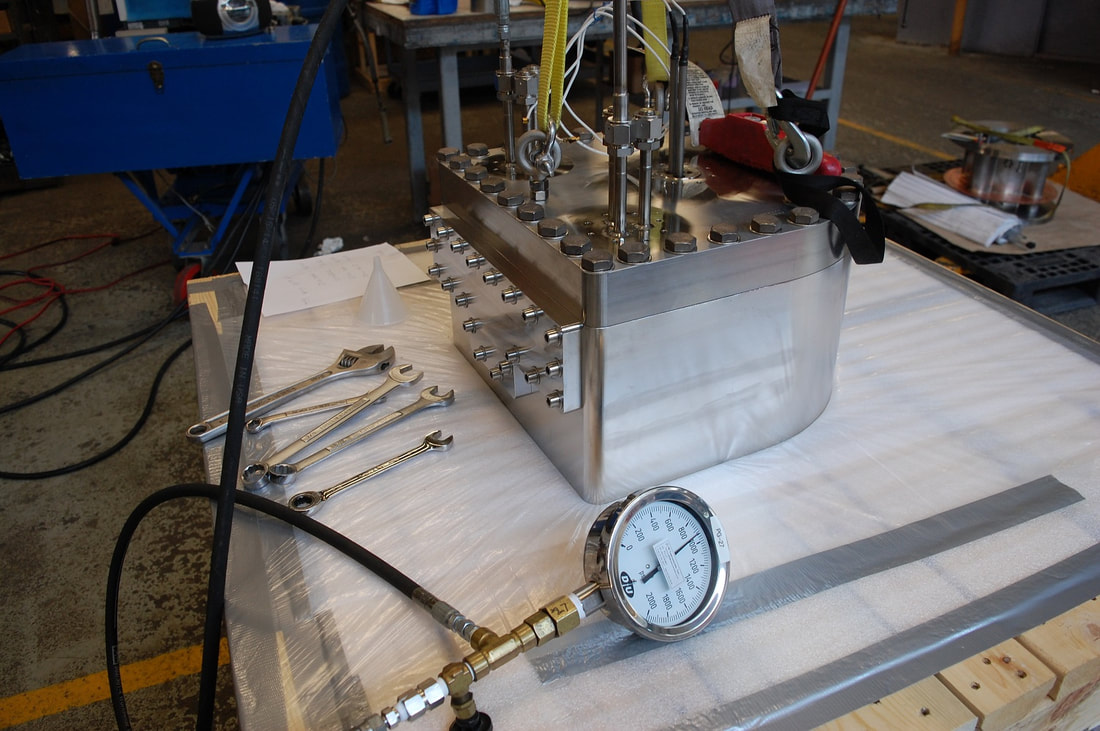

Pneumatic Pressure Testing

|

Pneumatic pressure testing of an industrial process chamber

|

All ASME code stamped Section VIII pressure vessels must undergo a pressure test. Pneumatic pressure testing is meant as a verification of the vessel design and workmanship. The test must always be performed after all other fabrication steps are complete. Nitrogen is used to pressurize the chamber. Pneumatic pressure testing is inherently more dangerous than hydrostatic tests. All vessels must be examined under the requirements of UW-50, which requires that all openings, welds, and attachments be examined before testing.

The minimum required test pressure for a pneumatic test is: Minimum Pneumatic Test Pressure = 1.1 x MAWP x LSR - MAWP = Maximum Allowable Working Pressure - LSR = Smallest ratio of the allowable stress at test temperature to the allowable stress at the design temperature of the materials used in the vessel construction. The Code requires the temperature of the vessel and its contents are the same and between a range of 30°F above the minimum design metal temperature (MDMT) and 120°F. After these tests are performed, the vessels are finally stamped to display that they meet the ASME Code and Meyer Tool standards, ensuring the safety of our customers and their projects. |