We are not your typical welding or machine shop. The projects we are most competitive on involve some unique feature or performance requirement that puts it just out of reach for your run-of-the-mill fab shop. We apply the skills we have honed servicing the National Lab industry for the past 50 years to each and every one of our projects.

WE MAKE TOUGH JOBS LOOK EASY

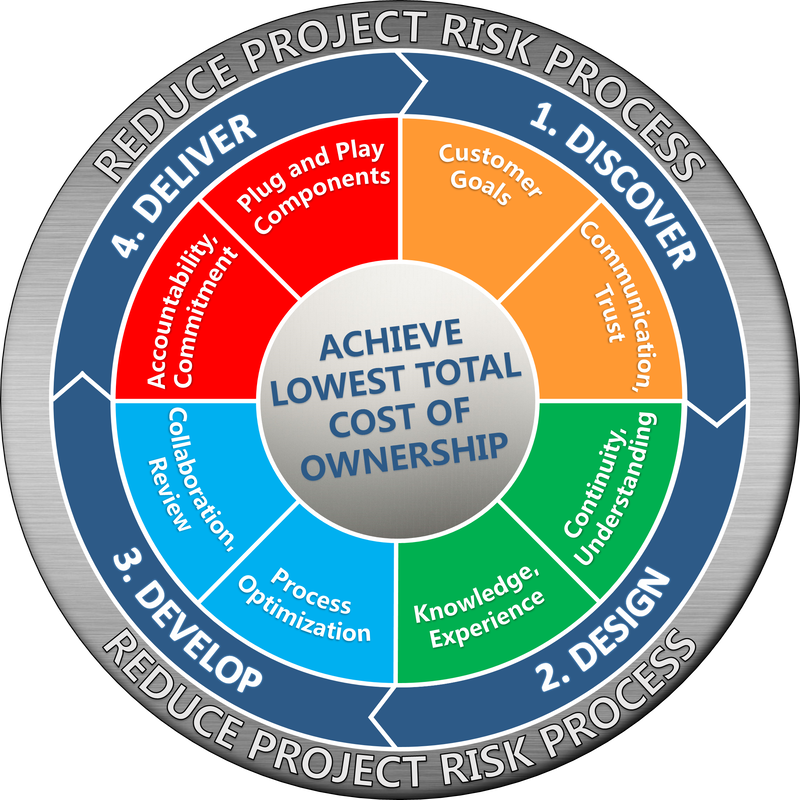

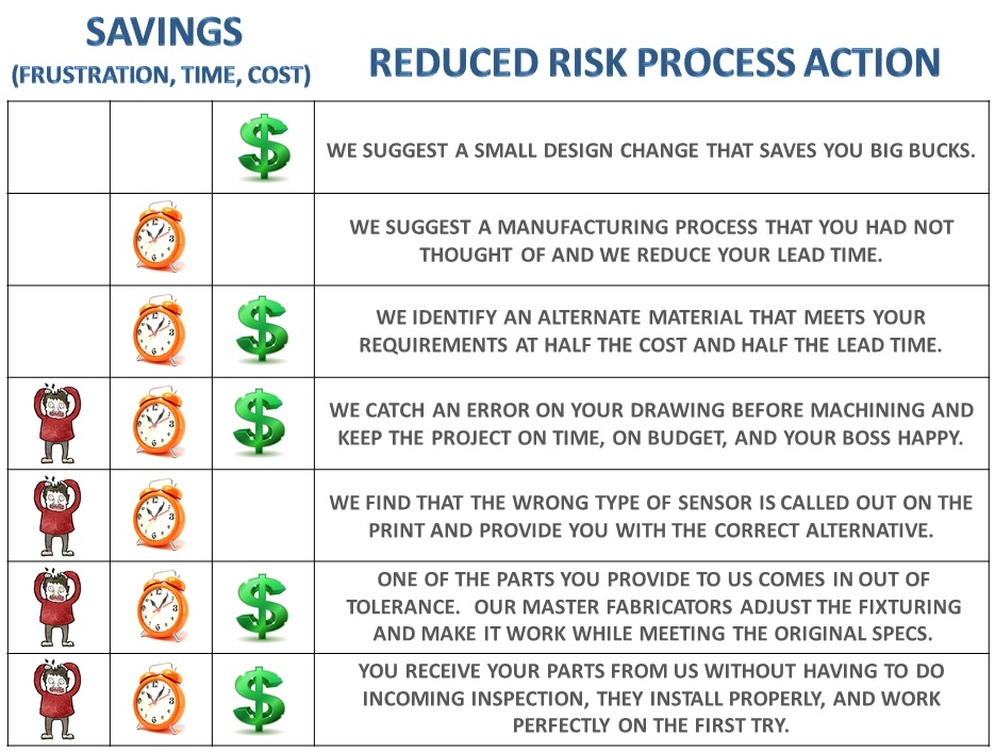

Our customers choose Meyer Tool because our "Reduce Project Risk Process" saves you time, money, and frustration over the life of your project.

1. Discover - Understanding Your Needs

Every project has a dedicated project engineer. The first step after an order is received is to have a pre-kickoff meeting with all shop and engineering personnel. The preliminary project plan is reviewed and all risky job attributes are identified and mitigation steps are brainstormed.

2. Design - Optimal Design For Fabrication

The project engineer reviews the mitigation steps and brainstormed issues from the pre-kickoff meeting. The engineer will contact the customer to obtain necessary clarifications and propose design optimization solutions. The engineer will also develop other risk mitigation strategies including: designing additional weld or machining fixturing, adding stock to raw material, adding final machining steps after welding, adding leak or inspection steps, changing the order of production operations, and even ordering additional spare material when necessary.

3. Develop - Detailed Production Plans

The project engineer integrates all risk mitigation techniques into a detailed project plan that consists of a step by step production traveler and a detailed set of production drawings. A final kick-off meeting is held with shop personnel to review the project plan and once again identify any areas for improvement. The job is released to the production floor once all parties agree that the production plan is complete.

4. Deliver - Build Superior Quality Products

The drawings and travelers are released to the shop and work begins on the project. Since we frequently work on prototypes and one of a kind projects we frequently identify new ways to streamline the production process on the fly. We utilize our Continuous Improvement Process, (CI Process), to track deviations to the plan and yet maintain the flexibility to adapt while maintaining the highest quality and shortest delivery time possible. We constantly search for better and faster ways to deliver products all the way to the point that ur product leave our dock doors.

By following these steps we are able to identify project risks and implement improvements early on in the process before they affect project cost, time, and quality.

We utilize our experience and flexible prototype driven fabrication processes to deliver high quality products at a reasonable price which saves you money and frustration compared to low cost / low quality alternatives.

Company InformationProud Member |

Contact UsPhone: 708-425-9080

Fax: 708-425-2612 Address: 4601 W. Southwest Highway, Oak Lawn, IL, 60453 Request a Quote |

|