Call: 708-425-9080

CUSTOM MACHINING SERVICES

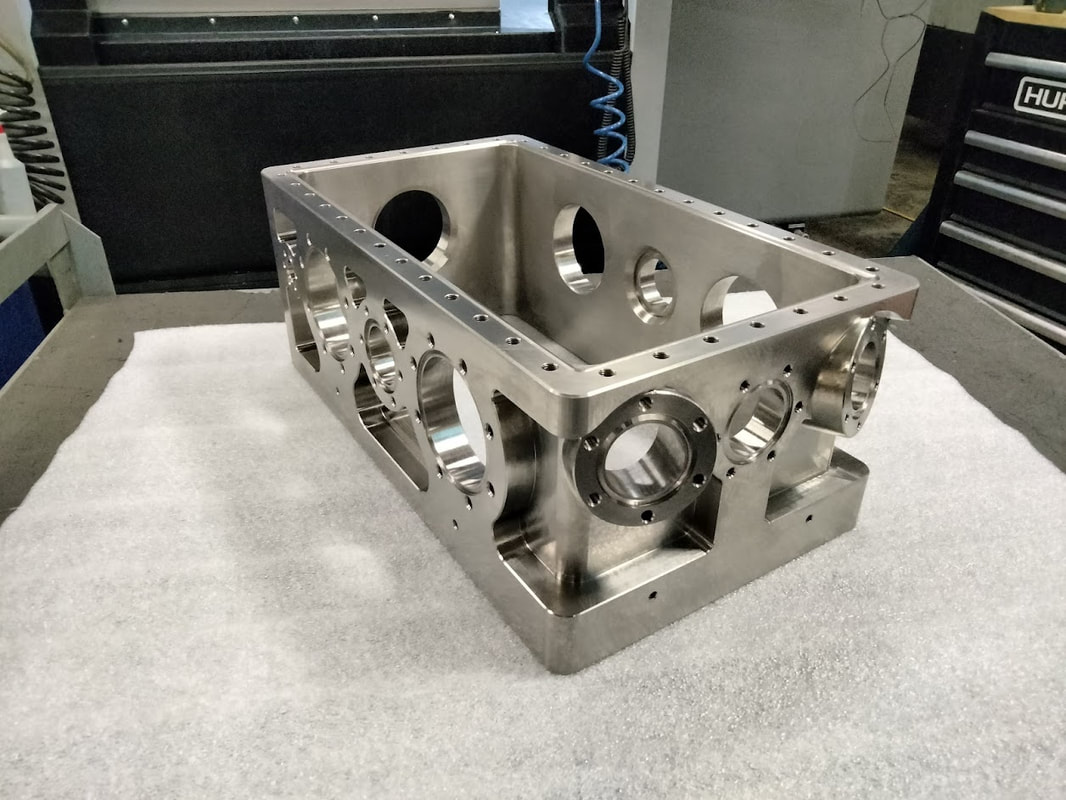

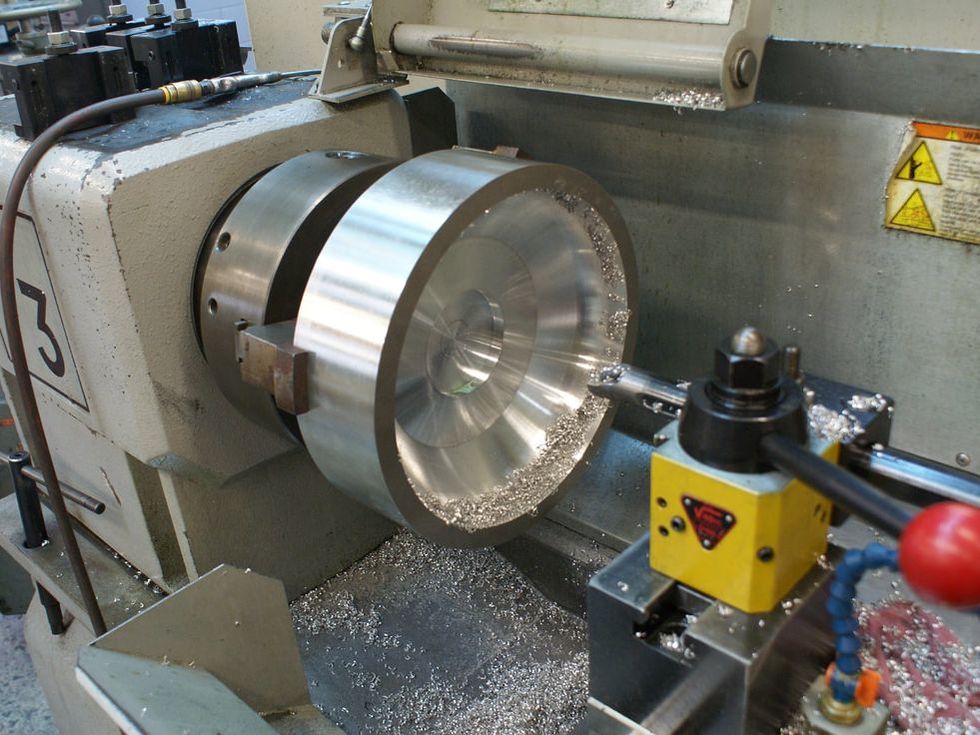

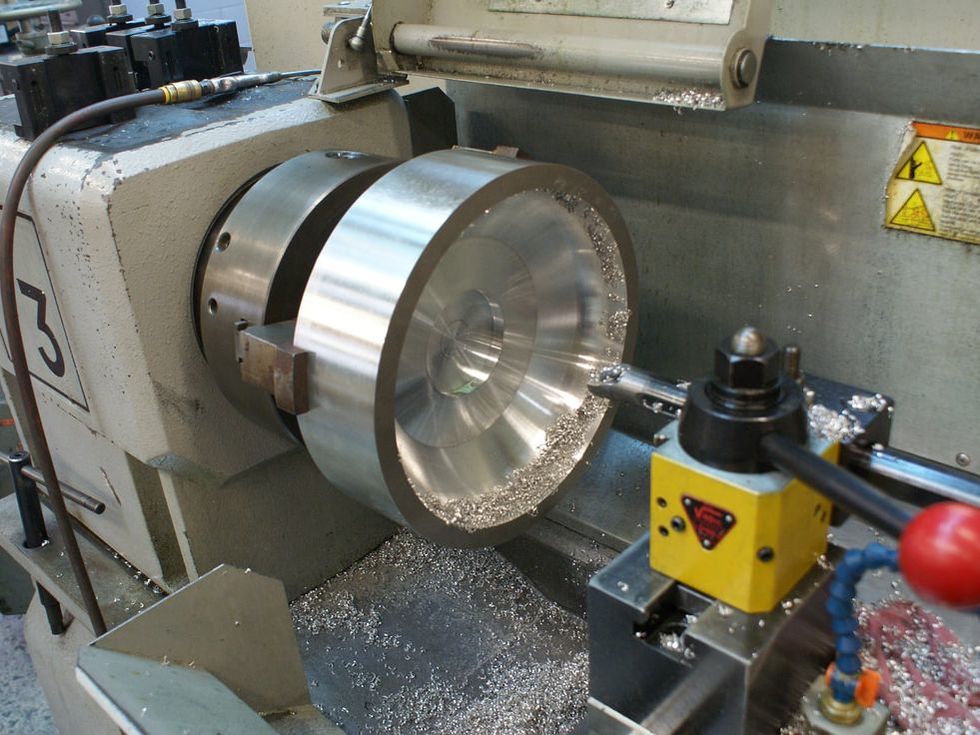

Lathe Turning - CNC Machining - Complex Machining

|

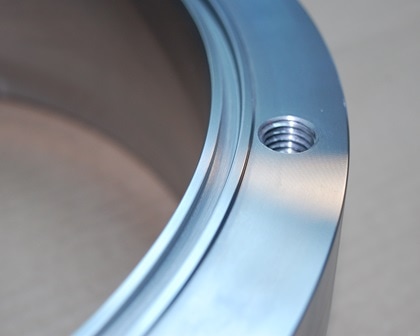

We are different from your standard machine shop in that a large part of our business comes from servicing the particle accelerator industry. This is a very niche industry where tight tolerances, immaculate surface finishes, and precision fit-ups are a way of life. We will approach your custom machining project with the same level of care that we apply when machining rare Niobium cavities that eventually make their way into a particle collider. |

Our sweet spot for machining projects revolves around low to medium sized production runs, (1-1000 units), of components that have something unique about them that requires additional attention to detail that other machine shops tend to overlook.

In addition to our internal machining capabilities we have an extensive supply chain of trusted suppliers that are able to fill in any unique machining operations that fall outside of our core capabilities.

In addition to our internal machining capabilities we have an extensive supply chain of trusted suppliers that are able to fill in any unique machining operations that fall outside of our core capabilities.