Call: 708-425-9080

WELDING SERVICES

Welding, Brazing, and Soldering

|

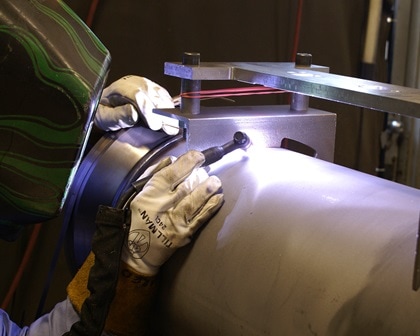

We have one of the most technically capable weld shops in the United States. Our welders are ASME Section VIII certified.

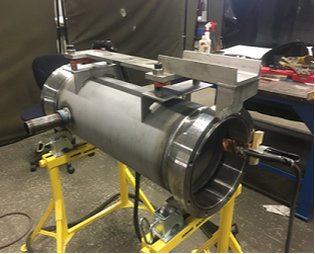

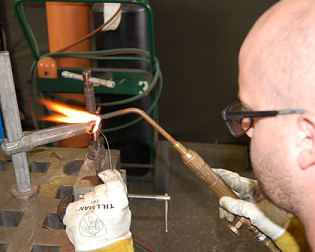

We have experience welding a diverse array of materials including Stainless Steel, Carbon Steel, Aluminum, Titanium, Platinum, Hastelloy, Inconel, Monel, and Niobium. We specialize in advanced TIG welding of Stainless Steel and Aluminum with additional strengths in MIG welding, copper brazing, and soldering. |

Thin walled tube welding, Aluminum vacuum chamber weldments, and Aerospace grade WPS requirements are par for the course when it comes to a typical day in the Meyer Tool weld shop.

Our welders are expert fabricators and blacksmiths capable of delivering jewelry store quality weldments whether it is on a one of a kind semiconductor process chamber or a production run of 100 ASME code pressure vessels.

Our welders are expert fabricators and blacksmiths capable of delivering jewelry store quality weldments whether it is on a one of a kind semiconductor process chamber or a production run of 100 ASME code pressure vessels.