|

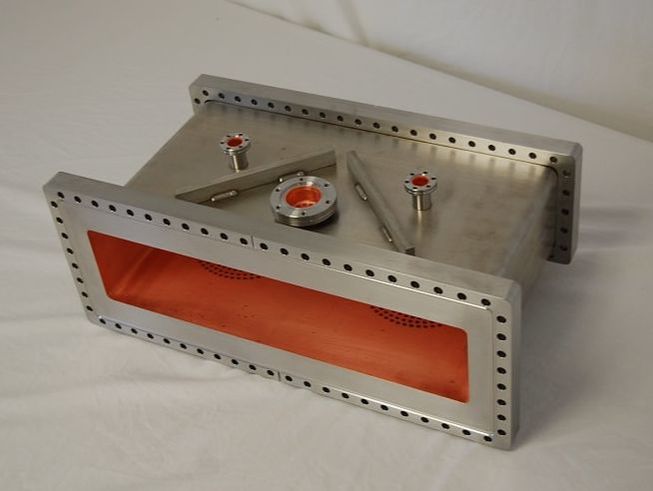

Specialists in Custom Pressure Vessels, Vacuum Chambers, Cryogenic Systems, Precision Weldments, and MORE!

|

Where SCIENCE FICTION

Becomes SCIENCE FACT

Custom Fabrication Company

We Know Custom!

Top Reasons Customers Use Meyer Tool

1. EXISTING QUALITY ISSUES - Your existing suppliers are having quality issues on critical components.

2. PRACTICAL KNOWLEDGE - You are developing a new product or prototype that requires skills related to pressure, vacuum, or cryogenic service that is just outside your core knowledge base.

3. COST REDUCTION - It makes sense for you to outsource the complex welding, machining, and fabrication operations that you do not run at full capacity.

4. ADDITIONAL CAPACITY - You need additional capacity for a complex or unique pressure, vacuum, or cryogenic system and you need a supplier that can hit the ground running.

2. PRACTICAL KNOWLEDGE - You are developing a new product or prototype that requires skills related to pressure, vacuum, or cryogenic service that is just outside your core knowledge base.

3. COST REDUCTION - It makes sense for you to outsource the complex welding, machining, and fabrication operations that you do not run at full capacity.

4. ADDITIONAL CAPACITY - You need additional capacity for a complex or unique pressure, vacuum, or cryogenic system and you need a supplier that can hit the ground running.

|

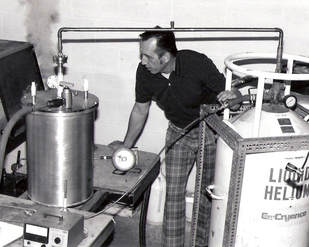

Meyer Tool founder, Frank Meyer, performing a helium leak test on a custom vacuum chamber

|

Quality - Value - PerformanceWe have developed our expert design and fabrication skills by servicing the particle accelerator industry for 50 years.

Your product might not be going into a particle collider, but we will fabricate it at a level of precision and quality so that it could! |

Certifications & Quality Standards

The Meyer Tool Difference

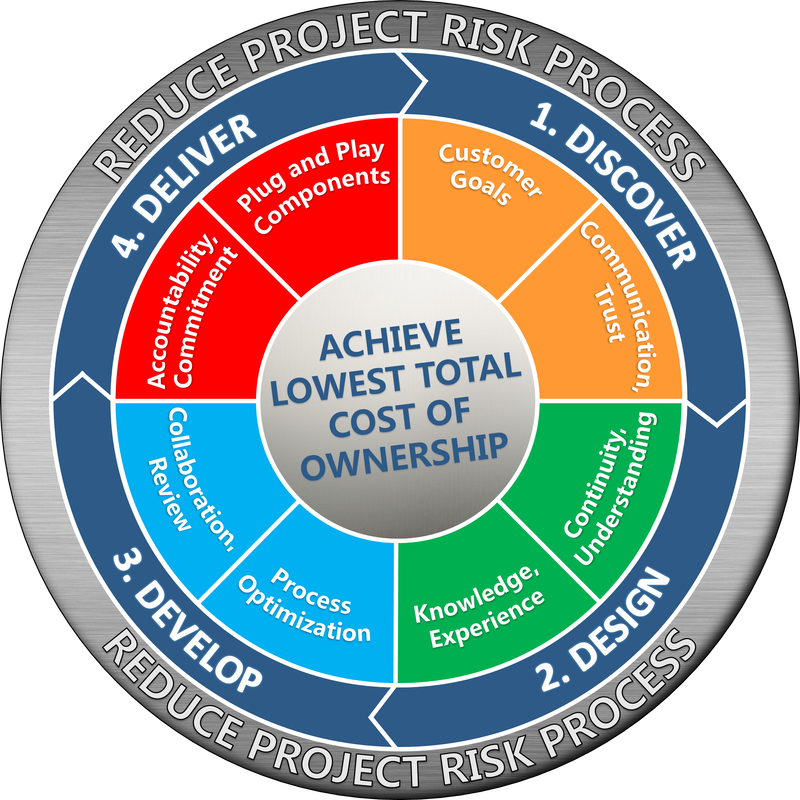

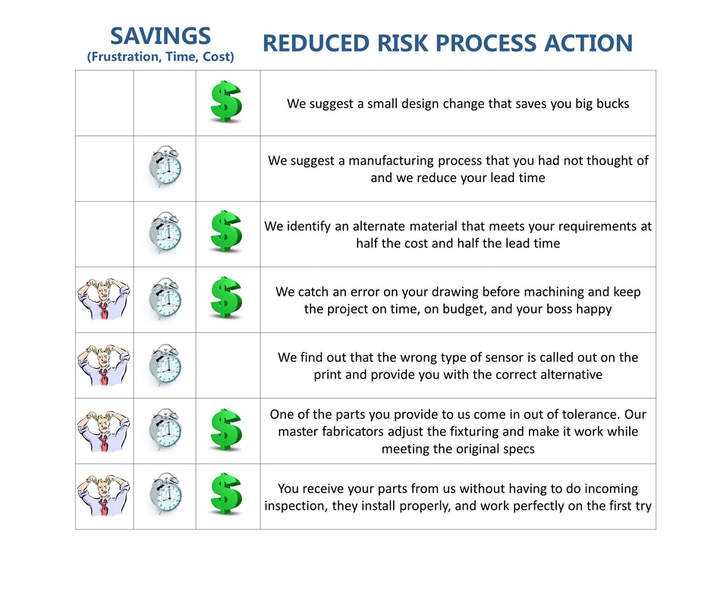

- We Address Risks Before They Become Problems -

We have developed our production processes around the fabrication of some of the most complex assemblies on the planet.

In order to become successful at fabricating complex short run prototype assemblies we were forced to develop our risk management skills. We find ways to reduce frustration, time, and cost by constantly looking for process improvements.

In order to become successful at fabricating complex short run prototype assemblies we were forced to develop our risk management skills. We find ways to reduce frustration, time, and cost by constantly looking for process improvements.

Meyer Tool Reduce Project Risk Process

1. Discover - We work to understand your needs2. Design - We integrate your needs into the product design3. Develop - We turn your design into a manufacturing process4. Deliver - We manage the process and deliver exceptional resultsBy following these steps we are able to identify project risks and implement improvements early on in the process before they affect project cost, time, and quality.

|

Company InformationProud Member |

Contact UsPhone: 708-425-9080

Fax: 708-425-2612 Address: 4601 W. Southwest Highway, Oak Lawn, IL, 60453 Request a Quote |

|