Call: 708-425-9080

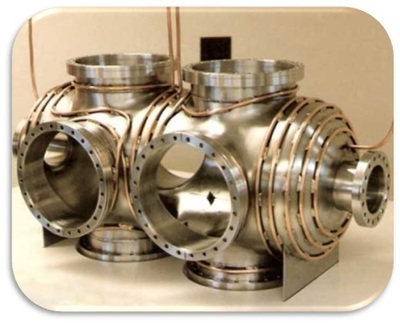

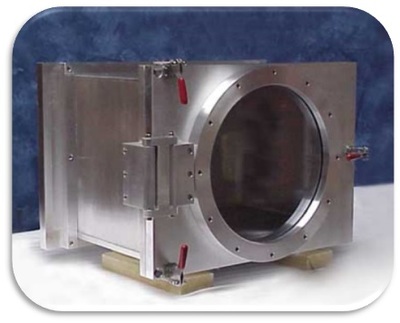

CUSTOM STAINLESS STEEL VACUUM CHAMBERS

The vacuum chamber is one of the most challenging pieces of process equipment to make. Welds must be completely airtight. Distortion due to high loads can create leak paths around access ports, and material outgassing can affect the process being performed. Experience is essential to avoid problems. Meyer Tool has the experience needed to avoid these problems with vacuum chambers.

Design Considerations for a Vacuum Chamber

We have been designing and building custom vacuum chambers for over 40 years. During that time we have accumulated a wealth of expertise and insight. The first step is to designing custom vacuum chambers is defining the chamber’s intended purpose. Key considerations include:

Material outgassing affects both pump-down time and processing conditions inside the vacuum chamber. A stainless steel vacuum chamber yields the lowest outgassing rate, although aluminum performs almost as well. The disadvantage of aluminum is that moisture bonds to the surface whenever the doors are opened. This increases pump-down time and reduces maximum chamber throughput.

Vacuum chamber geometry is another critical aspect. A sphere forms the strongest shape and is easy to keep clean inside. However, spheres and hemispheres present manufacturing challenges, especially in larger sizes. For this reason, a custom vacuum chamber often takes a cylindrical shape.

Surface finish has a big impact on how well the vacuum chamber performs by influencing both cleanliness and desorption rate. Polishing operations are usually needed after machining to achieve the desired condition.

- Level of vacuum required

- Process to be performed

- Need for heating or cooling

- Capacity

- Requirements for doors, viewing ports and feed-throughs

Material outgassing affects both pump-down time and processing conditions inside the vacuum chamber. A stainless steel vacuum chamber yields the lowest outgassing rate, although aluminum performs almost as well. The disadvantage of aluminum is that moisture bonds to the surface whenever the doors are opened. This increases pump-down time and reduces maximum chamber throughput.

Vacuum chamber geometry is another critical aspect. A sphere forms the strongest shape and is easy to keep clean inside. However, spheres and hemispheres present manufacturing challenges, especially in larger sizes. For this reason, a custom vacuum chamber often takes a cylindrical shape.

Surface finish has a big impact on how well the vacuum chamber performs by influencing both cleanliness and desorption rate. Polishing operations are usually needed after machining to achieve the desired condition.