Call: 708-425-9080

SPAFOA Members Meeting at SLAC and Berkeley Lab

October 29, 2015

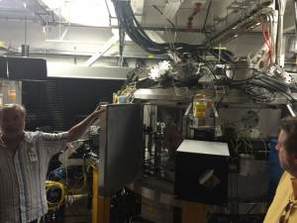

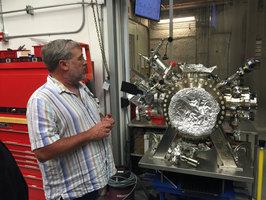

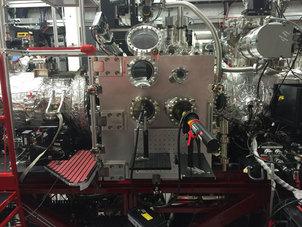

Berkeley Lab SPAFOA Meeting

Berkeley Lab SPAFOA Meeting

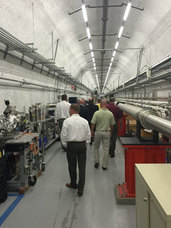

On September 22, 2015, the Superconducting Particle Accelerator Forum of America (SPAFOA) held a members’ meeting with a full day at the Stanford Linear Accelerator National Laboratory (SLAC) and a half day at the Lawrence Berkeley National Laboratory (LBL).The day at SLAC was hosted by the Laboratory’s Director, Dr. Norbert Holtkamp, and was an informational session on the LCLS-II project. SLAC is the lead laboratory on the project and the accelerator will be built and operated on their site.

SLAC has about 1600 employees and 3000 plus visiting scientists and students working on a variety of projects, not just LCSL-II. The laboratory’s 52 year old LINAC is still providing science. The Department of Energy is investing $1.6 billion in SLAC over the next 5 years. Other major projects at SLAC are: the Super CMDS-SNOLAB Liquid Argon Detector, FACET, the Facility for Advanced Accelerator Experimental Tests, MEC, Matter in Extreme Conditions, and LUSI, LCLS Ultrafast Science Instruments.

John Galayda, Project Director, LCLS-II provided an overview of the LCLS-II project, discussing the science goals and the practical matter of how the other laboratory partners will support the construction of the accelerator. Fermilab and Jefferson Lab will design and procure the cryomodule construction and cryogenic equipment, including the liquid helium plant. Berkeley Lab is responsible for the electron gun, associated injector systems, and the undulators. Argonne Lab is responsible for the undulator vacuum vessel, support of Fermilab with its SCRF cleaning facility and is working on undulator R&D and vertical polarization issues. John identified three of the largest risks to the project as being able to provide particle free cryomodules, maintaining a high Q in the cavities, and late deliveries of equipment due to the aggressive schedule.

Dave Schultz, LCLS-II Deputy Project Director, presented an overview of the LCLS-II Major Systems. Mike Fazio, Director of Technology & Innovation spoke on advanced R&D projects in RF. Jan Tulk, SLAC Chief of Staff, spoke on SLAC’s efforts on technology transfer and outreach to industry.

Barry Miller, LCLS-II Procurement Director, discussed the procurement structure between the Laboratory partners. There are expected to be $315 million in awards in a very short time frame. About 50% of these procurements will come from SLAC, the remainder from partner laboratories. All the individual laboratories will select their vendor base and send out their own requests for proposals. Within the next 18 months 70-80% of the procurements will be placed.

All these presentations will be made available on the SPAFOA website.

We will cover the Berkeley Lab visit in next month’s newsletter.

SLAC has about 1600 employees and 3000 plus visiting scientists and students working on a variety of projects, not just LCSL-II. The laboratory’s 52 year old LINAC is still providing science. The Department of Energy is investing $1.6 billion in SLAC over the next 5 years. Other major projects at SLAC are: the Super CMDS-SNOLAB Liquid Argon Detector, FACET, the Facility for Advanced Accelerator Experimental Tests, MEC, Matter in Extreme Conditions, and LUSI, LCLS Ultrafast Science Instruments.

John Galayda, Project Director, LCLS-II provided an overview of the LCLS-II project, discussing the science goals and the practical matter of how the other laboratory partners will support the construction of the accelerator. Fermilab and Jefferson Lab will design and procure the cryomodule construction and cryogenic equipment, including the liquid helium plant. Berkeley Lab is responsible for the electron gun, associated injector systems, and the undulators. Argonne Lab is responsible for the undulator vacuum vessel, support of Fermilab with its SCRF cleaning facility and is working on undulator R&D and vertical polarization issues. John identified three of the largest risks to the project as being able to provide particle free cryomodules, maintaining a high Q in the cavities, and late deliveries of equipment due to the aggressive schedule.

Dave Schultz, LCLS-II Deputy Project Director, presented an overview of the LCLS-II Major Systems. Mike Fazio, Director of Technology & Innovation spoke on advanced R&D projects in RF. Jan Tulk, SLAC Chief of Staff, spoke on SLAC’s efforts on technology transfer and outreach to industry.

Barry Miller, LCLS-II Procurement Director, discussed the procurement structure between the Laboratory partners. There are expected to be $315 million in awards in a very short time frame. About 50% of these procurements will come from SLAC, the remainder from partner laboratories. All the individual laboratories will select their vendor base and send out their own requests for proposals. Within the next 18 months 70-80% of the procurements will be placed.

All these presentations will be made available on the SPAFOA website.

We will cover the Berkeley Lab visit in next month’s newsletter.