Reducing Project Risk through Manufacturing Capabilities: Orbital Welding

Sometimes applying our Reduce Project Risk process and Step 4. Deliver, results not just in a robust manufacturing process and exceptional results for an individual project but yields new manufacturing capabilities that can be applied to meet other customer’s needs. Recently Meyer Tool was awarded a contract involving the welding of hundreds of tube-to-tube butt welds requiring 100% x-ray to meet the acceptance requirements of the ASME B31.3 Process Piping Code. A daunting task to meet these stringent non-destructive testing requirements; however, a task we felt we could accomplish with our existing robust manual GTAW (gas tungsten arc welding) processes and weld staff. As the majority of these welds involve a new material (INVAR 36) we first developed our manual GTAW WPS (weld procedure specification) and qualified it per the requirements of the ASME B&PV Section IX. We then qualified multiple welders to this new WPS.

|

Meanwhile our engineering staff was setting up the project travelers and manufacturing sequence. During this Step 3: Develop, of our Reduce Project Risk process, the possible increase in productivity and elimination of variation in the welds using the orbital welding process was discussed. While not part of our original estimation process for the project, we decided that the investment in an orbital welding system:

Orbital welding is the automated welding of tube or pipe in which the weld joint is held stationary while the weld arc rotates (orbits) around the weld joint. GTAW is not the only possible process but for Meyer Tool’s purposes it is the one best suited to our customers’ needs. The weld process itself can be autogenous (no filler metal) or utilize automatic wire feed weld heads to add filler metal. |

|

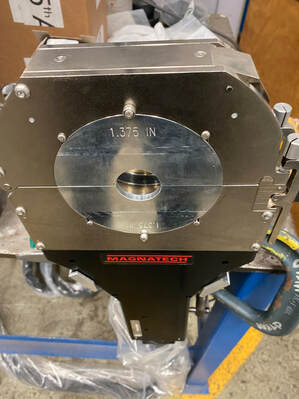

The tube-to- tube or pipe-to-pipe weld joint must be well fitted and secured within the ‘weld head’. The weld head is the device that holds the weld joint in place, provides the oxygen free purge cavity surrounding the joint, and holds the mechanism for rotating and providing the weld arc. Attached to the weld head is the power supply, which like a standard welder provides the electrical power to the weld head, plus it contains the programmable controller where the weld parameters are stored. Unlike a manual welding process, the fit up and purging of the joint is constrained in repeatability by the physical dimensions of the weld head and its tube/pipe collets. The weld process is precisely repeatable as the weld is performed to pre-developed and programmed parameters performed in an automatic process.

Orbital welding is best suited to processes that require:

We see this new tool as a long-term investment in our ability to provide our customers with the high-quality welded components they expect from Meyer Tool, using the latest in manufacturing technology.

Implementing our commitment to Reduce Project Risk involves not only applying our Process of Discover, Design, Develop, and Deliver to our customers' projects but also to discovering ways to improve our own internal manufacturing capabilities. Our customers from accelerator components to semiconductor demand the highest quality. Utilizing the latest in manufacturing technology to improve productivity and maintain quality is just one way we commit to achieving these goals. How we apply our Reduce Project Risk Process to our own business processes to better fulfill our customer needs is an important aspect of how Meyer Tool implements continuous improvement. Meyer Tool has more than 50 years of experience manufacturing cutting-edge components and assemblies. Our experience spans a wide range of materials, processes, and project sizes. Whether you’re building a single prototype or need production manufacturing support for your unique components, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs. Working on a project that requires manufacturing expertise? Give us a call at 708-425-9080 or fill out our RFQ form to get started! |