Reducing Project Risk: “Step 3 Develop” and Internal Training

Manufacturing companies face many challenges. One of the greatest challenges at Meyer Tool is to locate, train, and retain the skilled team members that comprise our staff; allowing them to "Build the Impossible". Applying the concepts of our Reduce Project Risk Process to our own business processes we are intensifying our existing efforts in training and continuous learning among our manufacturing and engineering team.

At Meyer Tool, we plan for the future, striving to maintain a balanced skill set of trainee, mid-level and long-term, experienced employees in every department. The shortage of experienced manufacturing personnel means, in order to grow, we must identify the right type of person and provide them the opportunities to learn and grow through structured and documented training opportunities and on the job shadowing experiences. The structured training opportunities are also a great refresher opportunity for our experienced employees.

At Meyer Tool, we plan for the future, striving to maintain a balanced skill set of trainee, mid-level and long-term, experienced employees in every department. The shortage of experienced manufacturing personnel means, in order to grow, we must identify the right type of person and provide them the opportunities to learn and grow through structured and documented training opportunities and on the job shadowing experiences. The structured training opportunities are also a great refresher opportunity for our experienced employees.

|

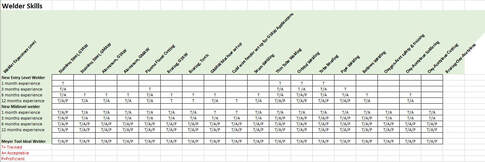

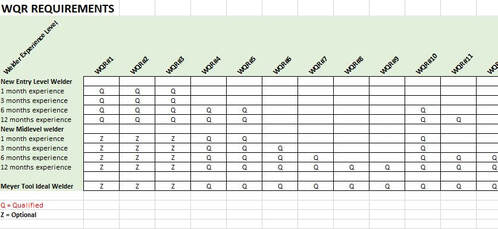

As part of this effort, we have developed a Welder/Fabricator training program that will commit two afternoons of formal training time per week to developing in our trainees and all our weld team members their skills, abilities, and certifications. These formal training sessions are a mix of theory and practical; ideal not only for our weld team members but also for our newest engineering staff members.

The program covers information and skills need at every level of experience. Topics include, General Knowledge, Safety, Weld and Brazing Basics, Welder Skills, Welder Qualification Requirements, Braze Qualification Requirements. Skills and goals for each level of experience are defined. Our engineering staff is documenting the training sessions, with photos, video, and drafting written Standard Training Procedures to be reviewed and approved by senior training and engineering staff prior to becoming modules in our formal training program. |

|

Copper-Stainless Torch Brazing

One of the first skill sessions involved copper-stainless steel brazing using silver alloy brazing filler. This is a skill used both in both cryogenic and UHV applications for structural heat transfer joints and pressure/vacuum boundary joints. Brazing is the joining of two metals, either the same or dissimilar, using a filler material. While superficially similar to welding, one very important distinction is the base metals in brazing are not brought to their melting point. You might note that this also seems to be a lot like soldering. Well, it is. An important distinction between soldering and brazing is that brazing is conducted at temperatures from 840°F to just below the melting point of the base materials being joined, while soldering is conducted below 840°F. |

Copper to Stainless Steel Silver Alloy Brazed Heat Transfer Blocks for Liquid Nitrogen Cooled Aluminum Shield

Copper to Stainless Steel Silver Alloy Brazed Heat Transfer Blocks for Liquid Nitrogen Cooled Aluminum Shield

In brazing and soldering, the joint is made by the solidification of the filler material. In brazing the flow of the melted filler material across the surface of the base materials being joined is accomplished through the process of capillary action. When the filler metal cools, a metallurgical bond forms, holding the base metals together. The joint design and clearances are dictated by the filler metal and base metal selections and the strength of joint you desire.

In brazing and soldering, the joint is made by the solidification of the filler material. In brazing the flow of the melted filler material across the surface of the base materials being joined is accomplished through the process of capillary action. When the filler metal cools, a metallurgical bond forms, holding the base metals together. The joint design and clearances are dictated by the filler metal and base metal selections and the strength of joint you desire.

The experienced engineers and manufacturing staff at Meyer Tool understand proper process and techniques to produce quality braze joints for both heat transfer and pressure/vacuum boundary application. It is critical that this knowledge be taught to our next generation of engineers and fabricators. Training the next generation is just one aspect of how we apply our Reduce Project Risk Process our own business processes to better fulfill our customer needs. Meyer Tool has more than 50 years of experience manufacturing cutting-edge components and assemblies. Our experience spans a wide range of materials, processes, and project sizes. Whether you’re building a single prototype or need production manufacturing support for your unique components, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs.

Working on a project that requires manufacturing expertise?

Give us a call at 708-425-9080 or fill out our RFQ form to get started!

Working on a project that requires manufacturing expertise?

Give us a call at 708-425-9080 or fill out our RFQ form to get started!