Call: 708-425-9080

Proper Torque for Conflat Flange Bolts

|

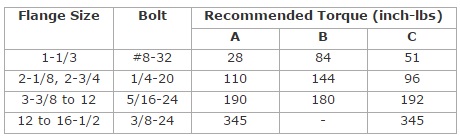

Many conflat flange users tighten the bolts until the faces of the flange are brought "metal to metal" and find that this is a reliable method of obtaining a leak-tight seal. The flange, in effect, provides a built-in gauge to determine when the gasket has been adequately deformed. The only drawback of this method might be that there is a possibility that the bolts will be over-tightened. Another approach would be to tighten the bolts to a specific torque. Many manufacturers of conflat flanges offer recommended values for the bolt torque. A sample from three manufacturers is given below:

|

While there is good agreement for the larger sizes, there is a considerable spread in the recommended torque for the smaller flanges. What is the correct torque to use? As a bolt is tightened, a force is applied to the gasket and an equal and opposite tensile stress is applied to the bolt. A widely used rule is that the bolt may be tightened until this stress reaches 75% of the yield stress for that material. While it may be possible to compress a gasket with less torque, taking the bolts to this torque will not result in damage to the bolt and there is generally little incentive to use a smaller torque.

|

The question then becomes how to relate the bolt torque to the bolt tensile stress. If friction could be neglected then it would be simple to relate the torque applied to a bolt to a resulting force. Turning a screw through an angle of 2π advances the screw a distance of P, where P is the pitch of the screw. The work done by the torque (torque multiplied by angle) must be equal to the work done by the force (force multiplied by distance) in the absence of friction.

|

or

In reality, the effects of friction are usually significant. There is friction between the head of the screw and the flange (or washer) and between the threads.

Db and Dn are the diameters of the bolt and nut, Θ is half the angle of the thread and k is a coefficient of friction. This sometimes appears with a factor of 12 inserted if T is in foot-pounds and P is in inches. In practice there is a large range of variation of friction factors depending on the materials, the use of lubricants, the use of a washer and the conditions of the surfaces. In a very rough way, the pitch of a bolt or a screw scales with its diameter, with larger diameter fasteners having larger pitches. The friction factors also scale as the diameter. Since all three terms scale, at least in a rough way, with diameter we can collect those terms into a single term that is proportional to diameter.

Where k is a factor determined by measurements, D is the diameter of the bolt and F is the tensile load of the bolt. A very rough average value of k is 0.2 , however, smaller values are possible if the threads are lubricated. Larger values would be expected if the surfaces are corroded. If the fasteners are 18-8 or 304 stainless steel then the yield strength is 42,000 psi and our maximum tension is 75% of this or 31,500 psi. Taking the 8-32 screw as an example, the stress area is 0.014 in2 and our maximum force is F = (0.014 in2)(31,500 psi) = 441 lbs and from the formula above our maximum torque is T = (0.2) (0.164 in) (441 lbs) = 14.4 in-lbs. This is on par with values of maximum torque recommended by fastener manufacturers for this screw. All of the suggested torques for 1.33" conflat flanges are considerably higher than our estimate and the maximum torque values suggested by some fastener manufacturers. Of course, these estimates are conservative and experience would suggest that cold working may significantly increase the yield strength of 18-8 or 304 SS, particularly in the smaller diameter fasteners.

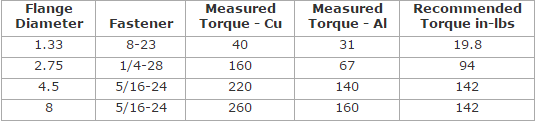

In table 2 we compare some carefully measured torques1 required to bring flanges "metal to metal" with the maximum torques recommended by a fastener manufacturer. In every case, compressing a copper gasket requires considerably more torque than is commonly recommended for that fastener. As expected, the aluminum gaskets require considerably less bolt tension to compress. Aluminum gaskets are necessary on aluminum conflat flanges. They may be helpful on stainless steel flanges if it is desirable to have lower bolt torque; such as in locations that are difficult to reach. Comparing tables 1 and 2 we note that the torque required to bring the flanges together often differs from the recommended torque.

Applying too much torque to a bolt will cause the bolt to stretch irreversibly and reduce the area of the bolt. Continuing to tighten the bolt will cause it to stretch further and eventually the bolt will fail. Bolts that show signs of deformation should be discarded. Some vacuum workers do not attempt to reuse 1.33" conflat flange screws because a significant number are distorted after one use.

Meyer Tool is often asked about using conflat flanges in pressure applications. Conflat flanges are manufactured and sold as vacuum components and are not intended for pressure applications. There are a number of factors to consider in applying them in pressure applications. Clearly, the added stress on the bolts due to internal pressure can be a factor, particularly if the bolt stress is high from compressing the gasket only.

Tightening a bolt to a specific torque does not necessarily guarantee that a particular bolt strain will be achieved because friction is often unknown or poorly controlled. Tightening the bolts to bring the flanges "metal to metal" provides a means of compressing the gasket in a reproducible way. However, the strain in the bolts is likely to approach the yield point when the gasket is fully compressed and care should be taken not to over tighten the bolts. Lubricating the threads will allow you to compress the gasket using the least possible torque. Tightening the bolts in the correct sequence is also important to having the gasket seat properly and achieving a reliable seal. At Meyer Tool, we strive to maintain the best high vacuum practices as another way of providing our customers with the lowest total cost of ownership.

1 D. Meekins "ASME Code Qualification of ConFlat Flanges"

Applying too much torque to a bolt will cause the bolt to stretch irreversibly and reduce the area of the bolt. Continuing to tighten the bolt will cause it to stretch further and eventually the bolt will fail. Bolts that show signs of deformation should be discarded. Some vacuum workers do not attempt to reuse 1.33" conflat flange screws because a significant number are distorted after one use.

Meyer Tool is often asked about using conflat flanges in pressure applications. Conflat flanges are manufactured and sold as vacuum components and are not intended for pressure applications. There are a number of factors to consider in applying them in pressure applications. Clearly, the added stress on the bolts due to internal pressure can be a factor, particularly if the bolt stress is high from compressing the gasket only.

Tightening a bolt to a specific torque does not necessarily guarantee that a particular bolt strain will be achieved because friction is often unknown or poorly controlled. Tightening the bolts to bring the flanges "metal to metal" provides a means of compressing the gasket in a reproducible way. However, the strain in the bolts is likely to approach the yield point when the gasket is fully compressed and care should be taken not to over tighten the bolts. Lubricating the threads will allow you to compress the gasket using the least possible torque. Tightening the bolts in the correct sequence is also important to having the gasket seat properly and achieving a reliable seal. At Meyer Tool, we strive to maintain the best high vacuum practices as another way of providing our customers with the lowest total cost of ownership.

1 D. Meekins "ASME Code Qualification of ConFlat Flanges"