A Cause For Celebration!

|

The beginning of September marked the first working day of Meyer Tool's 50th year in operation. The year-long celebration commenced with a company cookout with each employee receiving a 50th anniversary t-shirt.

For 50 years, Meyer Tool has taken great pride in participating in nearly every major Department of Energy scientific program in the fields of high energy and nuclear physics as an industry leader in cryogenic, pressure, and vacuum technologies. |

Our components are installed in the world's most powerful laser, most powerful particle accelerator, most powerful neutron source, at the South Pole, in advanced light sources, in solar cell production lines, semiconductor production lines, commercial sterilization accelerators, helium liquefaction plants, nano-particle production lines, and other harsh and demanding environments.

New 5-Axis Machine!

|

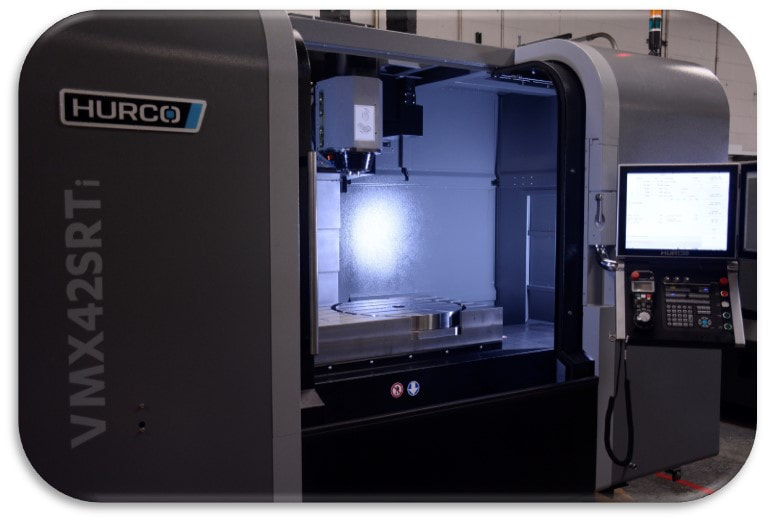

In a constant pursuit of continuous improvement as an organization, Meyer Tool expanded its' machine shop capabilities by adding a new 5-axis mill to its' existing fleet of CNC machines.

The Hurco machine will provide numerous benefits to our customers by:

|

Fabrication Tips

|

#3 Excessively Tight Tolerances Cost Money

It is important to consider tolerances and surface finish requirements specified on your drawings. Meyer Tool pays attention to the details so if you specify razor thin tolerances and tell us that you need to hit them, then we will do what it takes to meet your requirements. Other shops may quote you a price assuming that they can get away with giving you something less. That is not how we do business. We will always work with you to point out the various design features, tolerance changes, and component alternatives available that will optimize your design for fabrication. See more fabrication tips here |

Customer Satisfaction is our # 1 Priority

|

"The whole team at Meyer has been a delight to work with. My team and I are grateful for the excellent service and support." - Atlas Tool Works, Inc.

|

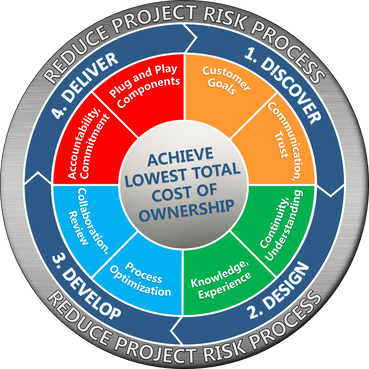

Why Choose Meyer Tool?Save Time, Money, and Frustration

Choose Meyer Tool because our "Reduce Project Risk Process" saves you time, money, and frustration over the life of your project 1. Discover - We work with you to understand your needs 2. Design - We integrate your needs into the product design 3. Develop - We turn your design into a manufacturing process 4. Deliver - We manage the process and deliver exceptional results! |

Request a Quote |

Contact UsMeyer Tool & Manufacturing Inc.

4601 W. Southwest Highway Oak Lawn, Illinois, 60453 Phone: 708-425-9080 Email: [email protected] |

Company InformationProud Member |

Contact UsPhone: 708-425-9080

Fax: 708-425-2612 Address: 4601 W. Southwest Highway, Oak Lawn, IL, 60453 Request a Quote |

|