Call: 708-425-9080

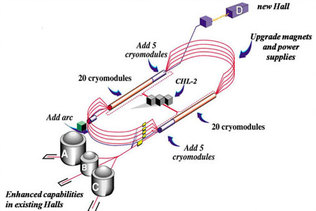

Meyer Tool receives multiple contracts for Jefferson Lab 12GeV Upgrade

December 17, 2009

|

We are pleased to announce that Meyer Tool has received three contracts totaling in excess of 1 million dollars from Jefferson Lab for work related to the 12GeV Upgrade to the Continuous Electron Beam Accelerator Facility (CEBAF). The three contracts involve components for the ten new Renascence cryomodules to be installed in the accelerator. The contracts are for manufacture of the cryomodule vacuum vessels, 50K thermal shields and the cryomodule cryogenic circuits subassemblies. Assembled at Jefferson Lab, the ten new cryomodules will each contain eight superconducting radio frequency (SRF) cavities operating at 2 kelvin. Five cryomodules will be installed in empty slots at the ends of each of the existing CEBAF linacs.

|

12 GeV Upgrade

12 GeV Upgrade

Providing components for SRF cryomodules has been a core competency of Meyer Tool for 20 years. Meyer Tool provided the original 180 Cryomodule Assemblies to the CEBAF project starting in 1989 with completion in 1992. Since then, Meyer Tool has provided SRF cryomodule components to Argonne National Laboratory, Cornell University, the Canadian Light Source, and the Spallation Neutron Source among others. These components include precision-machined cylindrical and rectangular vacuum vessels, ASME code stamped liquid helium vessels, copper and aluminum thermal shields, magnetic shields, airside radio frequency components, and other key components.

The cryomodule cryogenic circuits are internal helium piping subassemblies. The circuits are to be fabricated to the ASME B31.3 Pressure Piping Code. Meyer Tool’s ASME Section IX qualified welders will utilize our weld procedure specifications qualified for liquid helium temperatures to weld the seamless stainless steel piping. Our certified weld inspector will visually inspect welds. All subassemblies will be liquid nitrogen cold shocked and helium leak tested.

The 50K thermal shields are laser cut and formed copper shields requiring ASME Section IX brazing. Unlike previous CEBAF 50K thermal shields, these shields are formed in faceted rather than cylindrical sections. Again our certified welders will perform this function following cryogenically qualified brazing procedure specifications. All brazed pressure assemblies will be liquid nitrogen cold shocked and helium leak tested.

The cryomodule vacuum vessels are 32" diameter by 25 foot long stainless steel weldments requiring post weld machining of critical features. The vacuum vessels have been designed by Jefferson Lab to meet the intent of the ASME Boiler and Pressure Vessel Code Section VIII Division 1. Features of the vessel including weld sizes have been redesigned to meet the Code requirements. Meyer Tool’s extensive experience in building ASME code pressure vessels and large post-weld machined vacuum vessels makes us uniquely qualified to execute this project.

With extensive experience in manufacturing cryomodule vacuum vessels, Meyer Tool faces no unresolved challenges in fabricating the Renascence cryomodule vacuum vessels. There are however some key process issues that must be addressed in the developing the manufacturing sequencing. Some of these issues include specifying of the run-out and straightness of individual shells, the assembly and weld sequencing to maintain overall straightness, controlling weld shrinkage and distortion, and fixturing for final machining. We at Meyer Tool have been through this all before and have the knowledgeable and experienced personnel to do it again.

The cryomodule cryogenic circuits are internal helium piping subassemblies. The circuits are to be fabricated to the ASME B31.3 Pressure Piping Code. Meyer Tool’s ASME Section IX qualified welders will utilize our weld procedure specifications qualified for liquid helium temperatures to weld the seamless stainless steel piping. Our certified weld inspector will visually inspect welds. All subassemblies will be liquid nitrogen cold shocked and helium leak tested.

The 50K thermal shields are laser cut and formed copper shields requiring ASME Section IX brazing. Unlike previous CEBAF 50K thermal shields, these shields are formed in faceted rather than cylindrical sections. Again our certified welders will perform this function following cryogenically qualified brazing procedure specifications. All brazed pressure assemblies will be liquid nitrogen cold shocked and helium leak tested.

The cryomodule vacuum vessels are 32" diameter by 25 foot long stainless steel weldments requiring post weld machining of critical features. The vacuum vessels have been designed by Jefferson Lab to meet the intent of the ASME Boiler and Pressure Vessel Code Section VIII Division 1. Features of the vessel including weld sizes have been redesigned to meet the Code requirements. Meyer Tool’s extensive experience in building ASME code pressure vessels and large post-weld machined vacuum vessels makes us uniquely qualified to execute this project.

With extensive experience in manufacturing cryomodule vacuum vessels, Meyer Tool faces no unresolved challenges in fabricating the Renascence cryomodule vacuum vessels. There are however some key process issues that must be addressed in the developing the manufacturing sequencing. Some of these issues include specifying of the run-out and straightness of individual shells, the assembly and weld sequencing to maintain overall straightness, controlling weld shrinkage and distortion, and fixturing for final machining. We at Meyer Tool have been through this all before and have the knowledgeable and experienced personnel to do it again.