Call: 708-425-9080

Meyer Tool manufactures cryostat for astrophysics research

Cold Facts Buyers Guide (December 2005, Vol. 21, No. 5)

|

Meyer Tool & Mfg., Inc. has manufactured a cryostat for the QUIET (Q/U Imaging ExperimenT) experiment, a joint effort of a consortium from eleven universities and labs. Meyer Tool's engineers worked with Columbia University's Laura Newburgh, translating Columbia's design sketches and documents into manufacturing drawings and instructions.

Besides providing manufacturability assistance on the cryostat itself, Meyer Tool also designed the stand that allows the cryostat to be fully rotated for assembly of the internal instrumentation. QUIET originally began as a collaboration between experimental groups on CAPMAP (Princeton, Chicago, Miami, JPL) and CBI (Caltech) together with Columbia, joined by colleagues at Berkeley, Goddard Space Flight Center, and Harvard-Smithsonian. More recently experimental groups from Stanford and Oxford have joined. QUIET proposes to make very sensitive measurements of the polarization of the cosmic microwave background radiation, using the technology of coherent correlation polarimeters. It takes advantage of a breakthrough developed at JPL for the packaging of the polarimeters ("radiometer on a chip"). This facilitates mass production of the detectors, implementing hundred and thousand detector arrays. QUIET is a 5-year program to measure the CMB with large arrays of coherent detectors from the ground. The arrays will consist of receivers at two frequencies (40 and 90 GHz) and use multiple telescopes (3x2m + 1x7m) at 5,080m in Chile in the Atacama desert. The measurements will cover angular scales from a few arcminutes to a few degrees. Columbia University team with cryocooler. L to R: Seth Hillebrand, Robert Dumoulin, Laura Newburgh, Professor Amber Miller, Dr. Will Grainger. QUIET will study Stokes Parameters Q and U polarization of the Cosmic Microwave Background. In particular, these modes can be broken up in curl-free E modes and divergence-free B modes, each of which has encoded different information throughout the expansion and evolution of the universe. E-modes can be correlated with temperature and hence help to resolve some degeneracies in calculating cosmological constants from temperature data alone. Scientists also hope to extract the ionization history of the universe with more accurate measurements of E-mode polarization on large scales. B-mode polarization can be used as a direct probe into the universe before the surface of last scattering, so far not accessed. B modes are also created through gradational lensing, and hence provide a useful probe of the matter distribution of the universe. The amplitude of B-mode polarization is not known because they have never been detected and so we have also not been able to measure the B-mode foregrounds. QUIET will detect the B-mode and E-mode polarization signals to measure the amplitude and foregrounds. Employing new technology, replacing many large and unwieldy detector components into a single electronics chip, lets scientists create inexpensive, large arrays of detectors to increase the signal and detector area decreasing the amount of time for getting enough data to say something useful. Because the cryostat contains parts designed by everyone in the collaboration, Columbia says, they are "in the enviable position of trying to make everybody happy at the same time." Meyer Tool has machined the cryostat parts, and the cryostat is currently in New York being pumped down to vacuum and cooled. The Columbia team is testing various IR filters to reduce heating on the detectors and characterizing the window. From there, they will bid it a fond farewell as it travels to Chicago and Chile. This will complete the first phase of the cryostats for larger arrays observations in Chile. Afterwards, funding dependent, they hope to build more. Observing the polarized CMB demands exquisite sensitivity and freedom from systematic errors. QUIET is an integrated approach to characterizing the CMB polarization power spectra using very large 20% band-width arrays of 40 GHz and 90 GHz polarimeters capable of meeting these requirements. The QUIET arrays offer the most sensitive detector technology for ground-based CMB observations at 100 GHz or below, and build on established techniques for controlling polarization systematic errors. Each QUIET cryostat must mechanically support, cryogenically cool, and optically mount an array. In addition, they will house the associated warm electronics, provide a large microwave transparent high vacuum window, and shield the horn array from infrared radiation. |

|

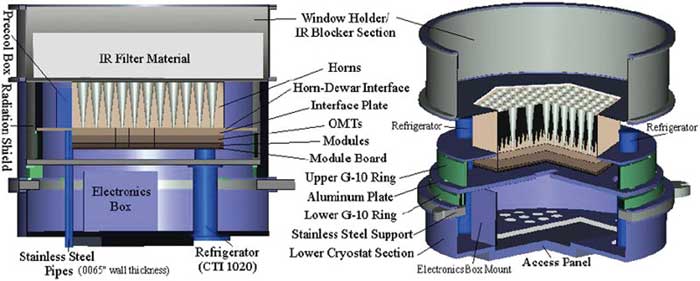

The figure above shows a schematic of the primary elements of the cryostat design using a CTI Gifford-McMahon refrigerator to provide cooling (two cold heads for demonstration cryostats, four for production version). The array is mounted on a G-10 ring providing support and thermal isolation. The window will be made of HDPE with an antireflection coating of expanded teflon; they expect losses of less than 0.05%. Scientists are investigating ways to minimize window deflection in each case and candidate IR blocking materials to be located between the window and the horn array.

The schematic view of the QUIET cryostat shows a 91 element array of W-band modules. Both G-10 rings make contact with the corresponding surfaces only through a fraction of their cross section in order to reduce thermal loading. Flexible printed circuit (not shown in the figure) connects the module board to the electronics back plane and the connectors in the bottom of the cryostat to the electronics box which resides in a 300K cavity beneath the aluminum plate. The horns are held at ≈∼20K and shielded from 300K radiation by a radiation shield (shown only in the figure on the left) held at 80K on the top and sides and the aluminum plate (also 80K) on the bottom. The window holder section is separable from the rest of the cryostat and can be enlarged (wider at the top than the bottom, where it mates to the rest of the cryostat) or shrunk as necessary to provide the minimum required space for the window and IR-blocking material while keeping the cryostat edges out of the field of view of the horn array.

A single cryostat design will be employed for both W-band and Q-band cameras in each phase. The cryostat design for the 400 element arrays will follow the same general design but will be 1.6 times as large.

The schematic view of the QUIET cryostat shows a 91 element array of W-band modules. Both G-10 rings make contact with the corresponding surfaces only through a fraction of their cross section in order to reduce thermal loading. Flexible printed circuit (not shown in the figure) connects the module board to the electronics back plane and the connectors in the bottom of the cryostat to the electronics box which resides in a 300K cavity beneath the aluminum plate. The horns are held at ≈∼20K and shielded from 300K radiation by a radiation shield (shown only in the figure on the left) held at 80K on the top and sides and the aluminum plate (also 80K) on the bottom. The window holder section is separable from the rest of the cryostat and can be enlarged (wider at the top than the bottom, where it mates to the rest of the cryostat) or shrunk as necessary to provide the minimum required space for the window and IR-blocking material while keeping the cryostat edges out of the field of view of the horn array.

A single cryostat design will be employed for both W-band and Q-band cameras in each phase. The cryostat design for the 400 element arrays will follow the same general design but will be 1.6 times as large.