Call: 708-425-9080

Meyer Tool & Manufacturing assists Indiana University Center for Exploration of Energy and Matter (IUCEEM) with Alpha Project

March 12, 2010

|

Professors S. Y. Lee and Paul Sokol of the Indiana University Center for Exploration of Energy and Matter (IUCEEM) are currently leading the design effort of a multipurpose electron accelerator called the Alpha Project (Advanced Electron-Photon Facility), which will be operated under a joint collaboration between Crane Naval Surface Warfare Center and IUCEEM. In total, a team of 25 physicists, engineers, technicians, and post doc/grad/undergrad students will be working on the ALPHA Project. This accelerator will serve the Department of Defense's requirements for testing radiation effects, as well as IU's interest in a compact high-brightness x-ray source. ALPHA will be composed of two main parts:

|

One of the primary requirements for Crane's radiation effects testing program is the uniformity of the electron radiation dose. It is necessary that the electron beam bunch does not have a frequency dependence in the (1-10 GHz) range since this would interfere with existing Crane diagnostics. In order to overcome this difficulty, the storage ring has been designed to produce a highly uniform electron pulse with a pulse length of up to 50 ns.

When operating as an X-ray source, the storage ring will form electron bunches approximately 10 ps in length that will collide with a laser pulse with approximately ~ 1 micron wavelength (near infrared-visible range). The collision between the electron beam and the laser beam will produce photons through the Inverse Compton Scattering process, with energies far greater than the laser beam. For a 50 MeV beam, it is possible to produce photon wavelengths ~ 0.03 nm (hard X-ray).

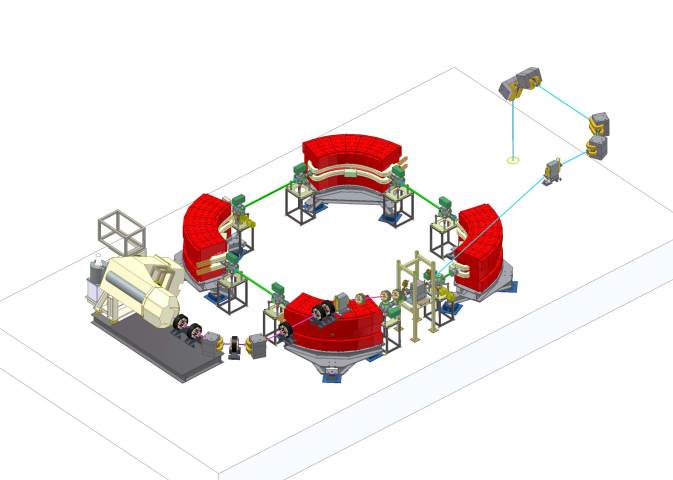

The CAD drawing below is the accelerator which is currently in construction phase. IUCEEM plans to run the first beam in March of 2010.

When operating as an X-ray source, the storage ring will form electron bunches approximately 10 ps in length that will collide with a laser pulse with approximately ~ 1 micron wavelength (near infrared-visible range). The collision between the electron beam and the laser beam will produce photons through the Inverse Compton Scattering process, with energies far greater than the laser beam. For a 50 MeV beam, it is possible to produce photon wavelengths ~ 0.03 nm (hard X-ray).

The CAD drawing below is the accelerator which is currently in construction phase. IUCEEM plans to run the first beam in March of 2010.

ALPHA will also serve as a user facility for the Indiana University community in a variety of scientific research areas. X-ray and VUV sources are of great importance to the scientific community for probing the structure and properties of biological and condensed matter systems. Small labs that conduct research in these areas typically utilize a rotating anode, which is a compact X-ray source. One of the drawbacks of the rotating anode is that it has a relatively low X-ray flux, which ultimately limits the quality of experiments that can be conducted. One of the great advantages of ALPHA is that it is possible to produce X-ray fluxes which are a factor of 10,000 times greater than the rotating anode.

Per Chandra Romel of IUCEEM:

Per Chandra Romel of IUCEEM:

|

“Meyer has contributed in a large way to the progress of the ALPHA project. They have fabricated (machined/welded) all of the dipole vacuum chambers, including chambers for the 20 degree, 45 degree, and 90 degree bending magnets.

"They worked with our engineers in the design development of the Lambertson magnet vacuum chamber, the magnet that guides the beam into the storage ring from the beam source. They have fabricated all of the ultra-high vacuum stainless steel beam lines to construct a 20 m storage ring, in addition to injection and extraction beam lines. They will be working with us in Phase II to develop beam position monitors (BPMs) for beam diagnostics. "Meyer not only has delivered high quality products in a timely manner, but they have offered their expert advice to help improve design and lean manufacturing.” Since its founding, Meyer Tool & Manufacturing has been involved in complex scientific and industrial projects like the Indiana University ALPHA project. We have earned a reputation of being able to manufacture equipment that others deem impossible to build. From project inception, we will work with our customers to develop low cost solutions based on years of experience in the design and manufacture of complex scientific equipment. Our goal is to provide our customers with top quality product at the lowest total cost of ownership. |