Call: 708-425-9080

Kevlar Supports for Cryogenic Vessels

Kevlar, a trademark of DuPont, is an "aramid" or aromatic amide. It has a very high strength to weight ratio. The specific gravity of Kevlar is 1.44 while the tensile strength is 3.5 GPa (500,000 psi). Kevlar is available in three grades, 29, 49 and 149, and the properties differ somewhat from one grade to the next. When Kevlar is spun the long polymer molecules tend to align along the axis of the fiber and the resulting fiber has some properties that are not isotropic. Kevlar fibers have a negative coefficient of thermal expansion along the axis of the fiber. Kevlar has been used as a replacement for steel in tires, as a component for helmets and as a material for sails among other applications.

The high strength and relatively low thermal conductivity of Kevlar (0.14W/mK at 100K) make it an interesting choice for thermal supports in cryogenic vessels, particularly in applications in which a very low heat leak and/or low weight are required. Kevlar has higher strength in tension than in compression, so to take best advantage of its properties the load would be suspended by strands or cables under tension. In spaceflight applications a Kevlar support system has been used to suspend a 3-He refrigerator. In zero-gravity the support system must prevent both motion and rotation of the load and must be maintained under tension to take up the expansion of the Kevlar as it is cooled. A similar support system has been used to support an adiabatic demagnetization stage of a refrigerator in an aircraft-based far infrared telescope. In more conventional ground-based cryostats Kevlar has been proposed as one of the elements in the CUORE experiment dilution refrigerator, which is to be installed at the Gran Sasso Underground Laboratory in Italy. In this experiment a total mass of 3300 lbs is to be cooled to 0.01K.

The high strength and relatively low thermal conductivity of Kevlar (0.14W/mK at 100K) make it an interesting choice for thermal supports in cryogenic vessels, particularly in applications in which a very low heat leak and/or low weight are required. Kevlar has higher strength in tension than in compression, so to take best advantage of its properties the load would be suspended by strands or cables under tension. In spaceflight applications a Kevlar support system has been used to suspend a 3-He refrigerator. In zero-gravity the support system must prevent both motion and rotation of the load and must be maintained under tension to take up the expansion of the Kevlar as it is cooled. A similar support system has been used to support an adiabatic demagnetization stage of a refrigerator in an aircraft-based far infrared telescope. In more conventional ground-based cryostats Kevlar has been proposed as one of the elements in the CUORE experiment dilution refrigerator, which is to be installed at the Gran Sasso Underground Laboratory in Italy. In this experiment a total mass of 3300 lbs is to be cooled to 0.01K.

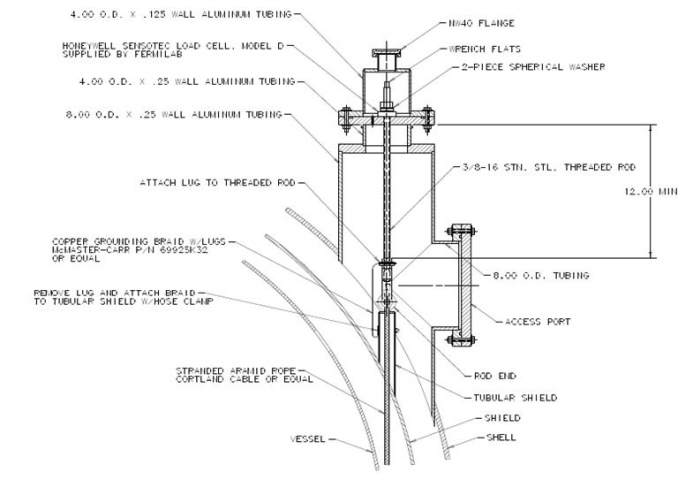

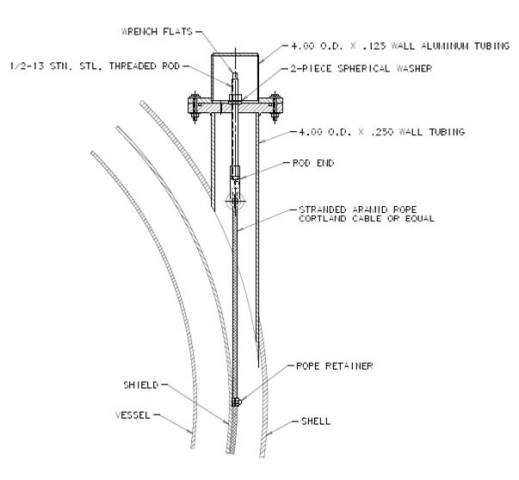

Stranded aramid rope is also being employed in the MINERvA experiment cryostat. This cryostat is a 2300 L liquid helium, vacuum isolated vessel used in a particle physics detector. It will be installed in a cavern 350 feet below the ground with limited space for a refrigeration system. Meyer Tool is in the process of fabricating this cryostat.

Some care must be taken in terminating a Kevlar cable to avoid breaking the strands. A loop may be formed in the end of the cable using clamps; however, the diameter of the spool supporting this loop must not be too small. It is also possible to glue Kevlar into a threaded member to facilitate attachment.

Some care must be taken in terminating a Kevlar cable to avoid breaking the strands. A loop may be formed in the end of the cable using clamps; however, the diameter of the spool supporting this loop must not be too small. It is also possible to glue Kevlar into a threaded member to facilitate attachment.

As more experience in the use of Kevlar supports in cryogenic applications is gained and as more data on the properties of Kevlar at low temperatures becomes available, it is likely that the high strength and low thermal conductivity of this material will lead to its application in an even wider array of vessels.

- A Cryogenic, Insulating Suspension System for the High Resolution Airborne Wideband Camera (HAWC) and Submillimeter and Far Infrared Experiment (SAFIRE) Adiabatic Demagnetization Refrigerator, George M. Voellmer et. al.

- Thermal Isolation of large loads at low temperatures using Kevlar rope, L. Duband, L. Hui and A. Lange, Cryogenics 33(6) , 643, 1993.

- The Cryostat of the CUORE Project, a 1-ton Scale Cryogenic Experiment for Neutrinoless Double Beta Decay Research, Davis Schaffer et al., 25th International Conference on Low Temperature Physics (LT25).