Ken Urban Celebrates 35 Years of Employment at Meyer Tool!

|

Servicing national laboratories, research universities and other advanced industries is not easy. Each project Meyer Tool receives comes a new series of challenges requiring our experienced team to work together to overcome. Completing these complex projects would not be possible without our Production Supervisor, Ken Urban, and he is happy to tackle them head on.

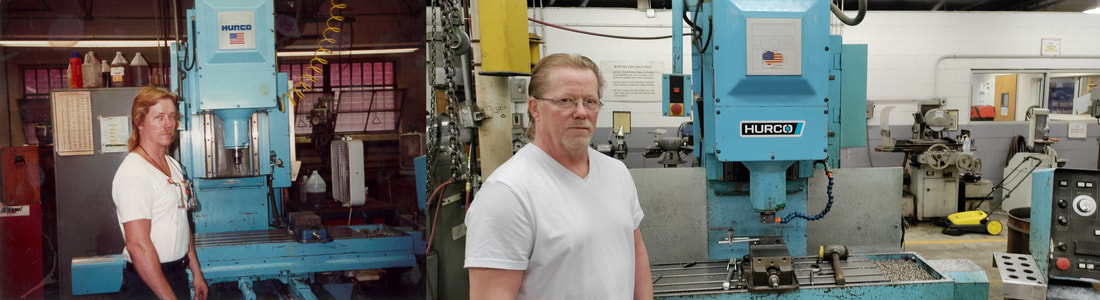

Ken began his tenure at Meyer in 1987 as a machinist, primarily operating Hurco and Bridgeport Mills with some occasional lathe work. Through the years, Ken grew his skills as a journeyman machinist vastly experienced on all Meyer Tool machine shop equipment. Today, Ken still operates some of the very same machines he started with (yes, we still sometimes use our old Bullard VTL!) but, as Production Supervisor, he is also heavily involved in our quoting process. Any time we receive a unique inquiry, we can count on Ken to understand the fabrication strategies needed to Reduce Project Risk and provide input on exactly what this project will require to be produced at the level of quality and precision Meyer Tool is known for. |

When asked why he stayed with Meyer Tool for so long, Urban replied: “There is always something different. I’m not just machining the same part over and over. I think that is really what kept me here all these years. Plus, our products go to some really cool places where we help our customers make a difference and change the world!” Using the skills and knowledge he has acquired over the past 35 years, Ken actively trains and inspires the next generations of Meyer Tool employees, including training up some of his own family. Quite a few Urbans have joined us over the years: among others, Ken’s son, Ken Urban Jr. is currently our Machine Shop supervisor, and last fall, his grandson Ryan joined the Meyer Tool Family, also in the machine shop, of course! During a time when employees switch jobs more than ever before, Meyer Tool is proud to be the type of company where employees can enjoy growing their career for over 30 years. That we have additional employees following at 10, 25, and even 40 years of service is a massive accomplishment. We truly are a learning organization where employees can be challenged for a lifetime solving various complex fabrication issues, while enjoying the sense of fulfillment that accompanies seeing these designs come to life. We are grateful people enjoy being part of our family so much they want their family and friends to become part of our team! Our strength is in our people, and Ken is a prime example. Meyer Tool owes a great deal of thanks to Ken and the Urban family for their role in Building the Impossible! |