Call: 708-425-9080

How to Select O-Ring Materials for Vacuum Applications

O-rings are available in a wide range of materials. In many applications the chemical resistance of the o-ring material to a particular chemical or process is the key factor in selecting an o-ring material. Some semiconductor processes can involve aggressive chemical agents as well as a need for high vacuum and low chemical contamination.

Vacuum Application Properties

In most vacuum applications the properties of interest are:

Cost may also be a consideration. With a common o-ring costing $0.15 in one material and $150.00 in another, it may sometimes be necessary to distinguish between characteristics that are desirable and those that are actually necessary.

- Suitability – is this material capable of making a reliable vacuum tight seal?

- Outgassing – how much absorbed gas and water vapor will be emitted and are other substances, such as unpolymerized monomer or polymerizing agents which could cause contamination issues, also emitted?

- Permeability – to what extent will gases be able to enter the chamber by diffusing through the o-ring?

- Resistance to compression set – will the o-ring tend to return to its original shape when compression is removed, or will it "set" and lose sealing pressure?

- Service temperature – will be an issue if the system requires bake out.

Cost may also be a consideration. With a common o-ring costing $0.15 in one material and $150.00 in another, it may sometimes be necessary to distinguish between characteristics that are desirable and those that are actually necessary.

O-Ring Material Classes

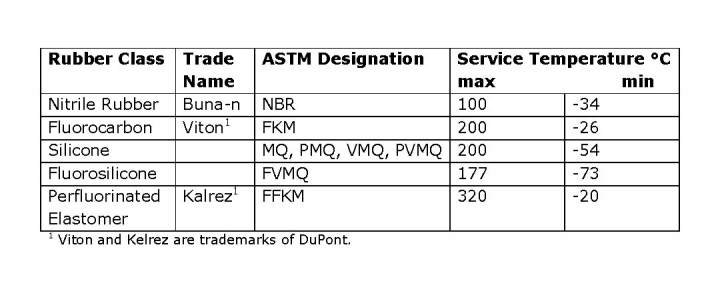

While many materials are suitable for making o-rings for vacuum service, a notable exception is Teflon. Teflon does not allow adequate compression to form a reliable, vacuum-tight seal. Some classes of materials that are suitable for o-rings for vacuum service include Nitrile (Buna-N), Fluorocarbon (Viton), Ethylene Propylene (EDPM), Perfluoroelastomer (FFKM, Kalrez) and silicone rubbers. Some common classes of materials are listed in Table 1.

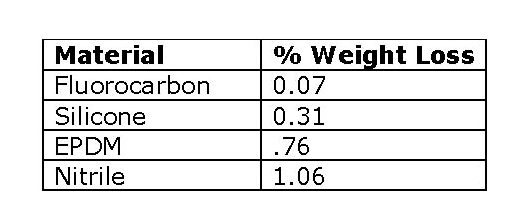

To compare the outgassing characteristics of some common materials we list the percentage weight loss after vacuum exposure in Table 2.

Fluorocarbons (Viton) perform relatively well, while Nitrile (Buna-N) has one of the higher outgassing rates. A high outgassing rate would be of particular concern in applications in which surfaces sensitive to contamination, such as optical components, were present. The gas load from degassing starts high and decreases with time as volatile material is pumped away. Typical initial degassing rates for Viton are reported to be close to 1 x 10-6 Torr-liter/cm2-s.

The permeability can be related to a volumetric leak rate by a permeability constant K:

Q = K ΔP A/d

where ΔP is the pressure difference, d is the thickness and A is the area.

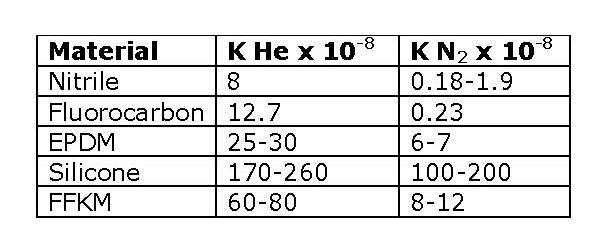

Some values of K at room temperature in units of 10-8 std cm3 cm/sec cm2 atm are given in Table 3. Permeation rates are higher at elevated temperatures. The permeation rate can be reduced by increasing the compression of the o-ring.

The permeability can be related to a volumetric leak rate by a permeability constant K:

Q = K ΔP A/d

where ΔP is the pressure difference, d is the thickness and A is the area.

Some values of K at room temperature in units of 10-8 std cm3 cm/sec cm2 atm are given in Table 3. Permeation rates are higher at elevated temperatures. The permeation rate can be reduced by increasing the compression of the o-ring.

Nitrile (Buna-N), which has poor outgassing characteristics, has a relatively low permeability; while silicone, which shows relatively little outgassing, has high permeability. Permeation of gas through o-rings can be a significant issue once the o-rings have been degassed. The gas load due to permeation can be reduced by using a double o-ring seal and evacuating the space between the o-rings. Even a rough "guard vacuum" between the o-rings greatly reduces the permeation rate across the inner seal.

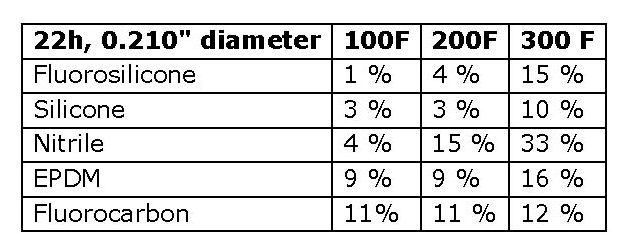

Compression set is the tendency of an o-ring to assume its compressed shape. Compression set can be expressed as a percentage by which a dimension (the cross section) fails to recover after compression is removed. If the compression set reaches 100%, then no sealing force is being exerted by the o-ring. The rate of compression set increases with temperature; however, the temperature dependence is quite different for different materials. In systems that are easily accessed for maintenance, compression set can be avoided by changing the o-rings frequently. Some values of compression set are given in Table 4.

Compression set is the tendency of an o-ring to assume its compressed shape. Compression set can be expressed as a percentage by which a dimension (the cross section) fails to recover after compression is removed. If the compression set reaches 100%, then no sealing force is being exerted by the o-ring. The rate of compression set increases with temperature; however, the temperature dependence is quite different for different materials. In systems that are easily accessed for maintenance, compression set can be avoided by changing the o-rings frequently. Some values of compression set are given in Table 4.

There is no one "best" o-ring material. The best choice for a material will depend on service conditions, frequency of maintenance, contamination sensitivity and cost considerations. At Meyer Tool, our experienced engineering staff can assist you in o-ring material selection. Offering such value added services is part of our commitment to ensuring that our customers achieve the "lowest total cost of ownership" through Reduced Project Risk.

In addition to partnering with an experienced, high-quality specialist such as Meyer Tool, The Parker O-Ring Handbook is a good source of information about o-rings, o-ring materials and o-ring applications. It was the source for much of the information in this article.

In addition to partnering with an experienced, high-quality specialist such as Meyer Tool, The Parker O-Ring Handbook is a good source of information about o-rings, o-ring materials and o-ring applications. It was the source for much of the information in this article.