Call: 708-425-9080

How to Review a Certified Mill Test Report

Rolling Mill

Rolling Mill

Whether manufacturing a large cryogenic module or a small flange adapter, using the correct material as determined in engineering for each component is critical. The Certified Mill Test Report is a tool used to ensure that received raw material matches the engineering and purchase order requirements.

A Certified Mill Test Report (CMTR) is a quality assurance document generated by the raw material manufacturer and provided with the material to intermediate suppliers and ultimately to a finished goods manufacturer like Meyer Tool. Whether it’s called a CMTR, Mill Test Report (MTR), Mill Certification, Metallurgical Test Report, or similar name, this document provides the end user of the raw material verification that the material received matches the requirements of their order. CMTRs are also used to maintain traceability of the material from its initial inception to its inclusion in a finished part.

A Certified Mill Test Report (CMTR) is a quality assurance document generated by the raw material manufacturer and provided with the material to intermediate suppliers and ultimately to a finished goods manufacturer like Meyer Tool. Whether it’s called a CMTR, Mill Test Report (MTR), Mill Certification, Metallurgical Test Report, or similar name, this document provides the end user of the raw material verification that the material received matches the requirements of their order. CMTRs are also used to maintain traceability of the material from its initial inception to its inclusion in a finished part.

CMTR Review Process

At Meyer Tool it is the Receiving Department’s responsibility to match received goods to supporting CMTRs and forward that information to the Project Engineer. The Project Engineer is responsible for review of the CMTR to ensure it meets the engineering and order requirements. Below we have summarized what our engineers are reviewing, so that only the correct materials are issued to the shop for manufacturing. This being another way we support our promise to Reduce Project Risk and achieve the lowest total cost of ownership for our customers

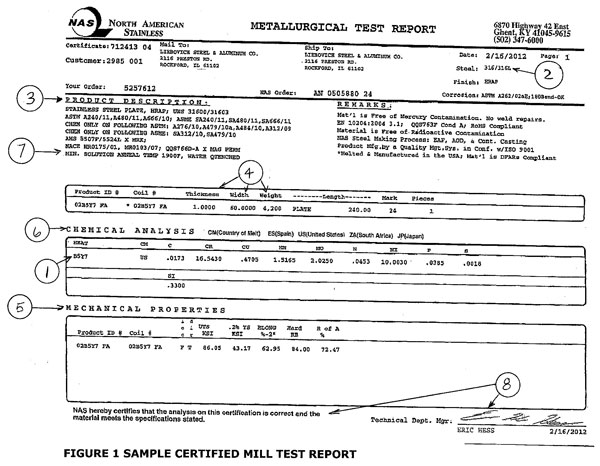

CMTR Example

CMTR Field Explanation

Balloon #01 - Material Heat Number

Material manufacturers can identify raw material in different ways, using lot, coil or other identifying numbers, but ultimately all CMTRs will identify the material with a Heat Number. The heat number is used to maintain traceability of the material. When matching a CMTR to its raw material all accompanying paper work and in many cases markings on the raw material itself must match the heat number on the CMTR.

Balloon #02 - Material Grade

Metal materials are produced in various grades. The CMTR identifies the grade of the material.

Balloon #03 - Product Specifications Met

CMTRs certify that the raw material meets the appropriate American Society for Testing and Materials (ASTM) or American Society of Mechanical Engineers (ASME) material product specification. ASME material specifications are required when fabricating Pressure or Vacuum Vessels to the ASME Boiler and Pressure Vessel Code. ASTM specifications are prefixed by an “A”, e.g. A240, while ASME specifications are prefixed by a “SA”, e.g. SA240. Often but not always the ASTM and ASME specification are identical. The product specifications that the raw material meets are listed on the CMTR.

Balloon #04 - Material Dimensions

The CMTR identifies the applicable dimensions of the raw material. In the case of plate material this would be the thickness, round bar the diameter, or flat bar the thickness and width. This information must match the order requirements.

Balloon #05 & #06 - Mechanical Properties / Chemical Analysis

The product specification lists the detailed requirements that the raw material must meet to be certified to that product specification and grade. The actual measured properties of the raw material are recorded on the CMTR for the identified heat number. These properties typically consist of the Mechanical Properties, (#05), and Chemical Analysis, (#6), The values listed on the CMTR must fall within the range or limits of the product specification for the raw material to be accepted for use.

Balloon #07 - Heat Treatment

Depending on the raw material, there may be other requirements in the product specification. For example, 300 series stainless steels require a specific heat treatment which must be recorded on the CMTR. The reviewer must identify all special processes in the product specification and confirm they are properly recorded on the CMTR.

Balloon #08 - Certified Mill Signature

Finally the CMTR must be certified with the signature of a responsible employee of the foundry or mill producing the raw material. See Figure 1, balloon #8.

Certified Mill Test Reports provide a record of traceability and properties of a raw material, ensuring that the material will perform in the way it was designed to. Deviations from product specification values can have large consequences, even causing a component failure. The ability to effectively review a Certified Mill Test Report to avoid such consequences is just one way Meyer Tool Reduces Project Risk and Achieves the Lowest Total Cost of Ownership for our customers.

The ability to effectively review a Certified Mill Test Report to avoid such consequences is just one way Meyer Tool Reduces Project Risk and Achieves the Lowest Total Cost of Ownership for our customers. Contact Meyer Tool today for more information.

Material manufacturers can identify raw material in different ways, using lot, coil or other identifying numbers, but ultimately all CMTRs will identify the material with a Heat Number. The heat number is used to maintain traceability of the material. When matching a CMTR to its raw material all accompanying paper work and in many cases markings on the raw material itself must match the heat number on the CMTR.

Balloon #02 - Material Grade

Metal materials are produced in various grades. The CMTR identifies the grade of the material.

Balloon #03 - Product Specifications Met

CMTRs certify that the raw material meets the appropriate American Society for Testing and Materials (ASTM) or American Society of Mechanical Engineers (ASME) material product specification. ASME material specifications are required when fabricating Pressure or Vacuum Vessels to the ASME Boiler and Pressure Vessel Code. ASTM specifications are prefixed by an “A”, e.g. A240, while ASME specifications are prefixed by a “SA”, e.g. SA240. Often but not always the ASTM and ASME specification are identical. The product specifications that the raw material meets are listed on the CMTR.

Balloon #04 - Material Dimensions

The CMTR identifies the applicable dimensions of the raw material. In the case of plate material this would be the thickness, round bar the diameter, or flat bar the thickness and width. This information must match the order requirements.

Balloon #05 & #06 - Mechanical Properties / Chemical Analysis

The product specification lists the detailed requirements that the raw material must meet to be certified to that product specification and grade. The actual measured properties of the raw material are recorded on the CMTR for the identified heat number. These properties typically consist of the Mechanical Properties, (#05), and Chemical Analysis, (#6), The values listed on the CMTR must fall within the range or limits of the product specification for the raw material to be accepted for use.

Balloon #07 - Heat Treatment

Depending on the raw material, there may be other requirements in the product specification. For example, 300 series stainless steels require a specific heat treatment which must be recorded on the CMTR. The reviewer must identify all special processes in the product specification and confirm they are properly recorded on the CMTR.

Balloon #08 - Certified Mill Signature

Finally the CMTR must be certified with the signature of a responsible employee of the foundry or mill producing the raw material. See Figure 1, balloon #8.

Certified Mill Test Reports provide a record of traceability and properties of a raw material, ensuring that the material will perform in the way it was designed to. Deviations from product specification values can have large consequences, even causing a component failure. The ability to effectively review a Certified Mill Test Report to avoid such consequences is just one way Meyer Tool Reduces Project Risk and Achieves the Lowest Total Cost of Ownership for our customers.

The ability to effectively review a Certified Mill Test Report to avoid such consequences is just one way Meyer Tool Reduces Project Risk and Achieves the Lowest Total Cost of Ownership for our customers. Contact Meyer Tool today for more information.