Call: 708-425-9080

How a Conflat Knife-Edge Seal Works

|

Conflat (CF) knife edge flanges are the most common type of dismountable flange used in ultra-high vacuum. Commonly called CF or Conflat flanges, the design was originally patented by Varian, Inc. in the early 1960’s. Very quickly, Conflat flanges become an industry standard due to the design’s reliability and repeatability. CF flanges are now a commodity item manufactured by a large number of vacuum component suppliers; generally manufactured to the ASTM E2734 Standard Specification for Dimensions of Knife-Edge Flanges. CF flanges are used in vacuum systems in ranges down to 10-13 torr.

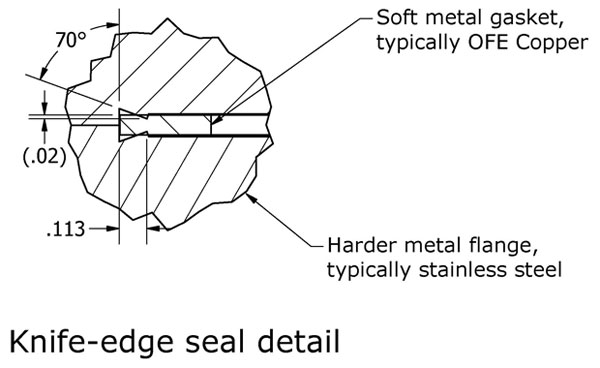

CF flanges are circular seals, however the profile of the knife edge is not dependent on diameter or a circular configuration and the limitation to circular seals is one based on the ability to machine the detail in a non-circular configuration.1 CF knife edge seals have a specific geometry designed to concentrate the tightening force of the bolts into a small width on the gasket. The material of the knife edge must be a harder material than the gasket material. Almost any combination of hard and soft vacuum compatible materials can be used as process needs dictate. The most common combination is a stainless steel knife-edge and OFE copper gaskets. Surface finish of the knife-edge is critical and must be 32 micro-inch or better. The gasket surface finish is less important. The sealing action fills up any small imperfections in the gasket surfaces. It is generally understood that if no scratches are visible in the gasket at 50x magnification, a vacuum seal can be achieved.1 |

The CF knife-edge utilizes a sealing ridge with the knife-edge normal to the gasket, the outer side of the detail is inclined at 70 degrees. The gasket is captured on its outer diameter in counterbore details on the opposing CF flanges. As the bolts between the mating flanges are tightened, the opposing knife-edges impress grooves into the softer metal gasket. The softer gasket material is extruded out from the knife-edge grooves, filling and sealing imperfections in the flanges and gasket around the knife-edge detail, forming the leak tight vacuum seal.

At Meyer Tool, our engineers and technicians are familiar with the details of designing and assembling leak tight CF flange joints. Understanding the why of how something works is part of our commitment to Reducing Project Risk, to ensure our customers achieve the lowest total cost of ownership.

Are you building a vacuum chamber requiring custom CF seals? Contact us for feedback on your design and manufacturability.

At Meyer Tool, our engineers and technicians are familiar with the details of designing and assembling leak tight CF flange joints. Understanding the why of how something works is part of our commitment to Reducing Project Risk, to ensure our customers achieve the lowest total cost of ownership.

Are you building a vacuum chamber requiring custom CF seals? Contact us for feedback on your design and manufacturability.

- Roth, Vacuum Sealing Techniques, American Institute of Physics, 1994.