Call: 708-425-9080

Custom Aluminum ASME Code Pressure Vessels

Large diameter, low pressure aluminum pressure vessel

Large diameter, low pressure aluminum pressure vessel

In the Reduce Project Risk section of our website we have several articles discussing the advantages and disadvantages of aluminum as the material of construction for vacuum vessels. We also see numerous inquiries about the suitability of aluminum for custom pressure vessels. A common thread among these inquiries is the use of aluminum in the fabrication of larger volume, relatively high pressure applications. In most cases, aluminum is being considered as a substitute for stainless steel and the main attraction of the aluminum is its lower density and an expectation that the custom ASME pressure vessel will have a much lower tare weight. Three key points to keep in mind when evaluating aluminum vs. stainless steel are:

- Weight: Stainless steel is approximately 3 times denser than aluminum but has a 2 to 3 times greater allowable design strength depending on aluminum alloy and heat treat condition.

- Material Cost: Historically per pound, stainless steel costs approximately 1.3 times to 1.5 times aluminum. However recently this cost advantage has been shrinking, especially in the heavier thicknesses.

- Manufacturing: According to AISI tests, aluminum is 4.75 times easier to machine than stainless steel. However, labor costs associated with welded vessels can minimize this advantage.

To help our customers develop conclusions regarding the suitability of aluminum for their custom ASME pressure vessel we will consider the following.

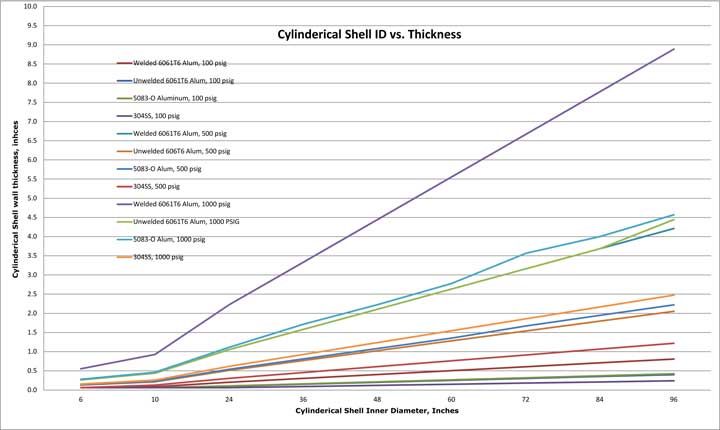

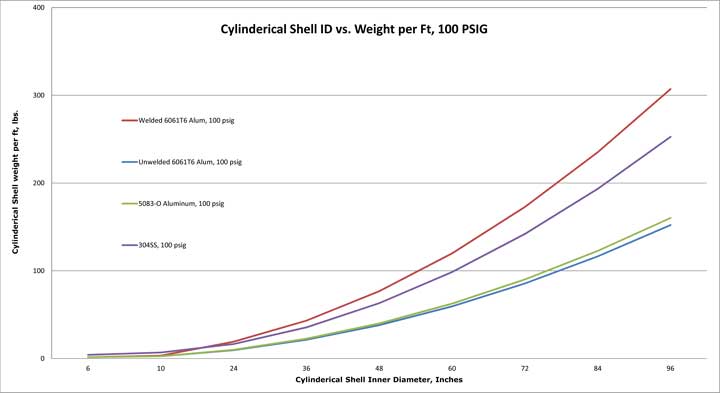

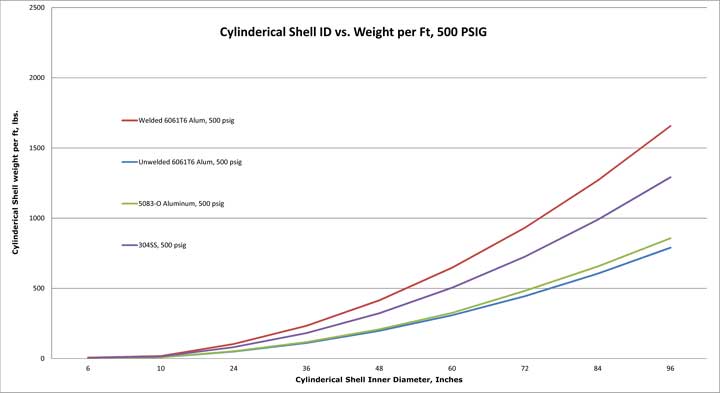

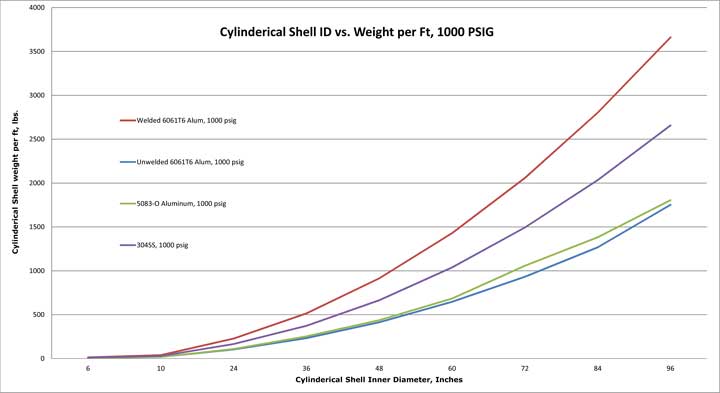

Four charts are presented. Shell ID vs. Thickness and Shell ID vs. Weight at 100 PSIG, 500 PSIG and 1000 PSIG. Click each graph to download a high-resolution PDF.

- Design: The common cylindrical shell, wall thickness based on ASME Section VIII Division 1 formula UG-27 (1) for circumferential stress. Excluding local stresses, such as nozzles, this formula normally defines the required wall thickness of a cylindrical shell under internal pressure. To simplify comparison we utilize a weld quality factor of E=1.

- Materials: Four materials in order of lowest to highest allowable stress, 6061T6 Aluminum in the welded condition, 6061T6 Aluminum in the un-welded condition, 5083-O temper Aluminum, and 304 stainless steel.

- Pressure: 100 psig, 500 psig, and 1000 psig.

- Temperature: 100°F design.

Four charts are presented. Shell ID vs. Thickness and Shell ID vs. Weight at 100 PSIG, 500 PSIG and 1000 PSIG. Click each graph to download a high-resolution PDF.

Conclusions:

This is, of course, a simplified analysis to illustrate the trend. In analyzing a real-world design, other factors have to be taken into consideration, including specific ASME requirements and manufacturability your custom ASME pressure vessel. Through Meyer Tool’s Reduce Project Risk process, our engineering staff can help develop the optimal design for your needs to achieve lowest total cost of ownership.

Understanding how to meet your custom ASME pressure vessel requirement, whether in aluminum or another material, is a part or Meyer Tool’s Reduce Project Risk Process. Whether you’re building a single prototype custom ASME pressure vessel or need production manufacturing support for your unique application, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs.

Working on a project that requires custom ASME pressure vessel manufacturing expertise?

Give us a call at 708-425-9080 or fill out our RFQ form to get started!

Notes:

- As diameter and pressure increase, the lower density advantage of aluminum is outpaced by the higher design allowable of the stainless steel until stainless steel designs actually weigh less than welded 6061T6 aluminum custom ASME pressure vessel designs.

- For larger diameter vessels, to regain the weight advantage of aluminum, welded 6061T6 vessels must be re-tempered or an alternative aluminum material with a higher allowable must be selected.

This is, of course, a simplified analysis to illustrate the trend. In analyzing a real-world design, other factors have to be taken into consideration, including specific ASME requirements and manufacturability your custom ASME pressure vessel. Through Meyer Tool’s Reduce Project Risk process, our engineering staff can help develop the optimal design for your needs to achieve lowest total cost of ownership.

Understanding how to meet your custom ASME pressure vessel requirement, whether in aluminum or another material, is a part or Meyer Tool’s Reduce Project Risk Process. Whether you’re building a single prototype custom ASME pressure vessel or need production manufacturing support for your unique application, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs.

Working on a project that requires custom ASME pressure vessel manufacturing expertise?

Give us a call at 708-425-9080 or fill out our RFQ form to get started!

Notes:

- For welded 6061T6 Aluminum, the ASME Boiler and Pressure Vessel Code requires a much lower allowable stress value be used in design. Pressure vessels utilizing this material must either be re-tempered to T6 condition or be fabricated in a manner that avoids welding to regain the higher allowable stress value for the T6 un-welded condition.

- 5083-O Aluminum was included as its allowable is used as the lower limit for welded H14 temper.

- Thickness calculated below ASME Section VIII minimum thickness adjusted to reflect minimum 0.063” thickness.

- The Aluminum materials’ allowable stress values vary with thickness.

- Aluminum materials have restrictive upper temperature limit requirements. Consult ASME Section II Part D for details.

- ASME Section II Part D also restricts maximum allowable thickness for product forms in Aluminum, this simplified analysis ignored this restriction.