Meyer Tool Installs Second CNC Lathe with Live Tooling

|

Implementing our commitment to Reduce Project Risk involves not only applying our Process of Discover, Design, Develop, and Deliver to our customers' projects but also to discovering ways to improve our own internal manufacturing capabilities. One aspect of this continuous internal improvement is the addition of the latest in manufacturing technology. The most current example of this is the HURCO TMM10i CNC lathe with live tooling installed in our facility at the end of June 2021. The second CNC lathe in our machining area to incorporate live tooling, this advanced feature allows us to combine precision turning capabilities with secondary milling and drilling operations. With advanced software and control capabilities this American built machine tool works seamlessly with our CAM software to allow direct 3D model to machining programming. With the movement to the use of limited dimensioned drawings provided with certified 3D models by many of our customers in the Semiconductor and Aerospace segments, this was a critical design feature identified when we developed the requirements we desired in a new CNC lathe.

|

|

Being American built and locally available, Hurco was able to deliver in a short order cycle. In just a few weeks our machining team has integrated the new lathe and made it a productive member of our lathe contingent. The new lathe’s specifications, especially the control features, are Ideal for the lower volume (10-100) part counts of precision cryogenic components we are running currently and the similar types of precision components that are used in the weldments and assemblies we manufacture in support of both our research and development and OEM customers. This investment in the latest in CNC lathe technology reduces production bottlenecks by increasing capacity both though the addition of the lathe itself, but also by decreasing programming and set up time.

|

|

Determining how new equipment investments can increase productivity, reduce lead times, and improve product quality are all aspects of how we apply our Reduce Project Risk Process to our own requirements. Meyer Tool has more than 50 years of experience manufacturing cutting-edge components and assemblies. Our experience spans a wide range of materials, processes, and project sizes. Whether you’re building a single prototype or need production manufacturing support for your unique components, Meyer Tool’s engineering and manufacturing team approaches each challenge using our Reduce Project Risk Process to support your needs.

Working on a project that requires manufacturing expertise? Give us a call at 708-425-9080 or fill out our RFQ form to get started! |

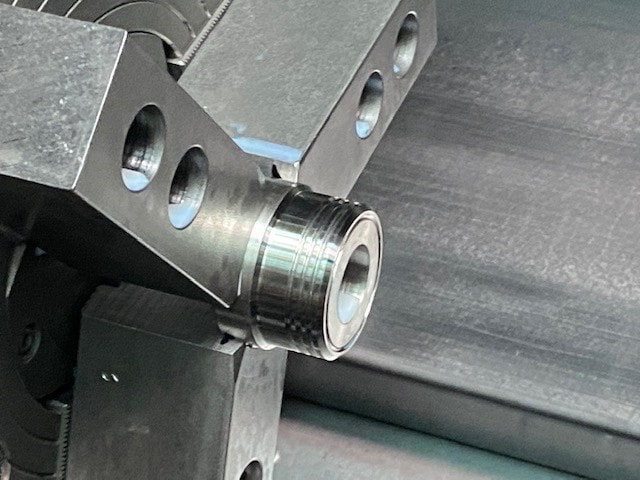

Meyer Tool’s new CNC Lathe with live tooling producing production parts just a few weeks after delivery.