Call: 708-425-9080

BEYOND SPECS: Thermal Shrouds

Why use a Thermal Shroud?

Example: Insulated Surface (MLI), 1W/m2 heat flux from 300K

Estimated cost of helium refrigeration:

Materials:

(High Thermal Conductivity, Ease of Fabrication, Cost)

COPPER

ALUMINUM

STAINLESS STEEL

The convenience of producing sound joints to copper with BAg solder is partially offset by the need to use corrosive flux. The flux must be thoroughly removed from piping to avoid the development of leaks.

ACTIVELY COOLED THERMAL SHROUDS:

Attach cooling lines or coils.

Copper - Soft Solder, BAg Solder or fasteners/clamps

Aluminum - Weld “Foot Tubing” or fasteners/clamps.

Mechanically attached cryo-cooler

- Primarily Intercept Radiation

- Also Intercept Heat Conducted Through Structure

- Practical Necessity

Example: Insulated Surface (MLI), 1W/m2 heat flux from 300K

Estimated cost of helium refrigeration:

- $60,000 per m2 per year if intercepted by LHe at 4K

- $4,200 per m2 per year if intercepted by LN2 at 80K

Materials:

(High Thermal Conductivity, Ease of Fabrication, Cost)

COPPER

- Traditional material for thermal shrouds. Easy to fabricate

- Soft Solder, Weld, Solder BAg, TIG (or torch) Braze BCuP

- Attach to SSTL: BAg Solder (corrosive flux)

- Fasteners (similar thermal contraction)

- TIG Braze with BCuP

ALUMINUM

- Light weight, flight applications

- Weld (brazing process not suitable for heat shields)

- Attach to SSTL: Explosion bonded joints

- Fasteners (spring loading may be required)

STAINLESS STEEL

- Convenient to weld, not a great conductor

The convenience of producing sound joints to copper with BAg solder is partially offset by the need to use corrosive flux. The flux must be thoroughly removed from piping to avoid the development of leaks.

ACTIVELY COOLED THERMAL SHROUDS:

Attach cooling lines or coils.

Copper - Soft Solder, BAg Solder or fasteners/clamps

Aluminum - Weld “Foot Tubing” or fasteners/clamps.

Mechanically attached cryo-cooler

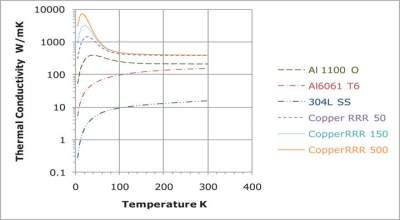

The thermal conductivity of copper and aluminum alloys depends strongly on the temper or hardness as well as on the alloy. Values reported for the thermal conductivity of C110 copper correspond approximately to those of copper having a residual resistance ratio (RRR) of 50.

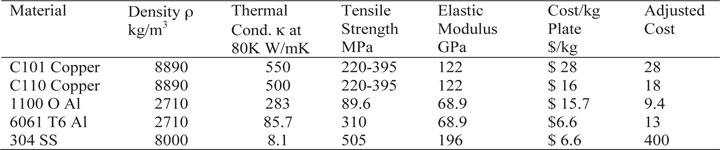

Material Cost Comparison:

Material costs for sheet/plate are averages from several commercial suppliers obtained in May 2011.

Material Cost Comparison:

Material costs for sheet/plate are averages from several commercial suppliers obtained in May 2011.

Conclusion:

In terms of material cost, aluminum is advantageous to copper for 80K thermal shrouds. At 80K the same thermal performance can be obtained at lower cost by specifying C110 copper over C101 copper. Similarly, the highly pure 1100 alloy of aluminum has a high thermal conductivity, but that is largely offset by its higher cost, leaving it with only a slight cost advantage over the 6061 alloy. Rely on Meyer Tool’s cryogenic expertise to Reduce Project Risk and achieve Lowest Total Cost of Ownership on your next thermal shroud.